What Is A Rigid Flex PCB?

Andwin provide Flex PCB and Rigid-flex PCB for customer, email us now for you PCB quote, Email is : contact@andwinfpc.com

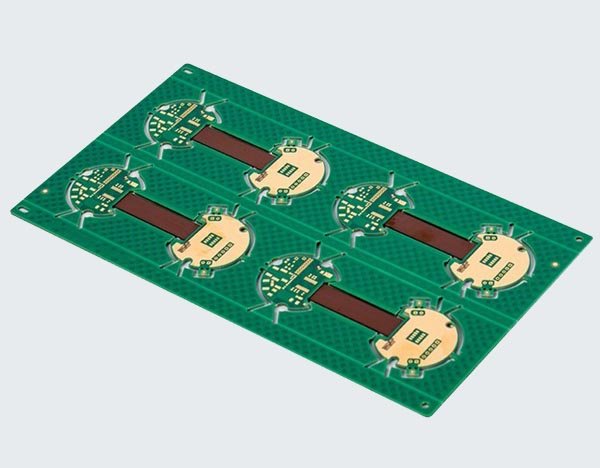

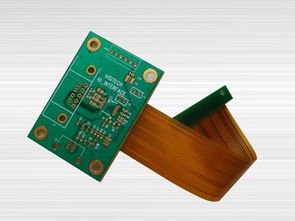

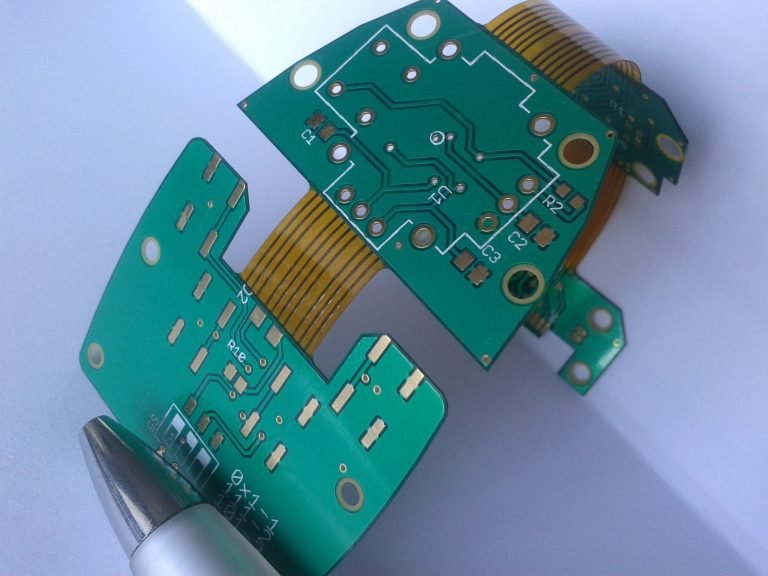

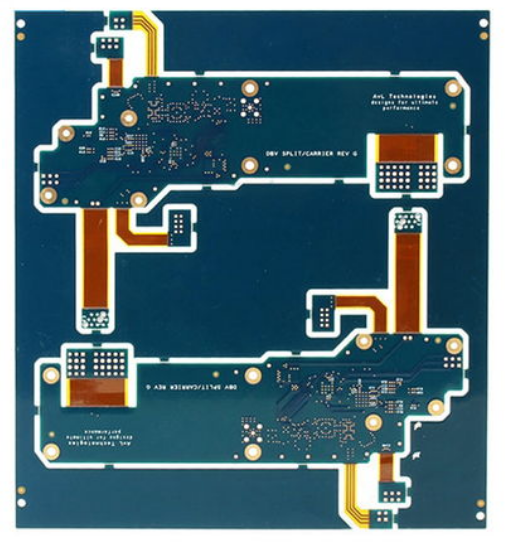

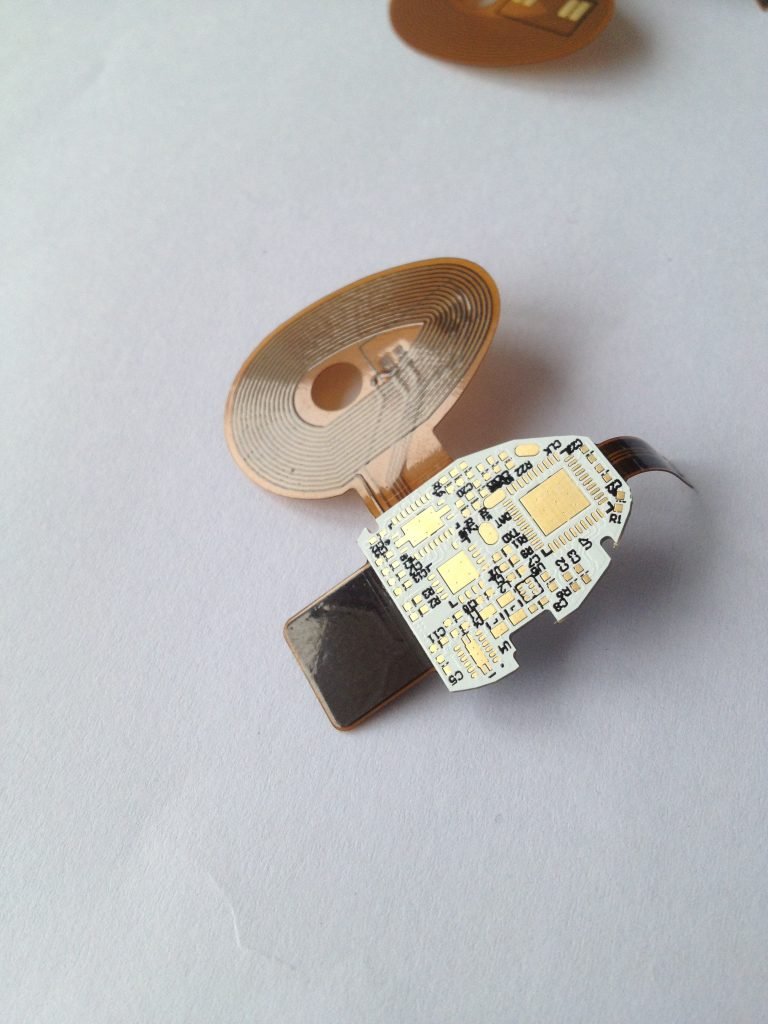

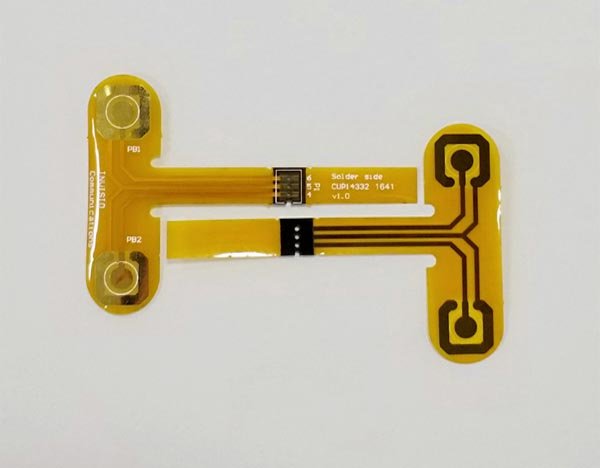

A rigid-flex PCB consists of multiple layers of rigid and flexible substrates that are laminated together. The rigid sections provide structural support and host components, while the flexible sections allow the board to bend and conform to the desired shape or fit into tight spaces. This combination enables the PCB to be more versatile and adaptable to various form factors and design requirements.

The rigid sections are typically made of FR4 or other rigid materials, while the flexible sections use polyimide or similar flexible substrates. These flexible substrates are thin, lightweight, and highly flexible, allowing the board to withstand repeated bending, twisting, or folding without compromising its functionality.

The rigid-flex PCB manufacturing process involves several steps, including designing the circuit layout, fabricating the rigid and flexible substrates, and then laminating them together using specialized adhesives. The circuit traces and vias are created using conventional PCB fabrication techniques, such as etching or plating, on both the rigid and flexible sections.

One of the primary advantages of rigid-flex PCBs is their ability to reduce the need for connectors and cables, which can be bulky, expensive, and prone to failure. By integrating the flexible sections directly into the board, the number of interconnections is reduced, leading to improved signal integrity, reduced assembly time, and enhanced reliability.

Rigid-flex PCBs are commonly used in applications where space is limited, such as portable electronics, medical devices, aerospace systems, and automotive electronics. Their ability to conform to complex shapes and withstand harsh environments makes them ideal for applications that require high reliability, durability, and miniaturization.

In conclusion, a rigid-flex PCB is a versatile circuit board that combines rigid and flexible materials to provide a compact, lightweight, and reliable solution for various electronic applications. Its unique construction allows it to adapt to different form factors and withstand challenging environments, making it a popular choice in industries that demand high-performance and space-saving solutions.

Benefits Of Flexible PCB

It ensures high circuitry density, thermal management, and enhanced reliability for enhanced performance.

About Andwin FPC

Since our founding in 2006, Andwin FPC has been leading Flex & Rigid-flex PCB technology across several markets,

we are proud to serve a wide range of industries, including aerospace, medical,automotive, and telecommunications.

Our flexible PCB and Rigid-flex PCBs are used in a variety of applications,from simple electronic devices to complex systems that require high reliability and performance.

At Andwin, we are dedicated to providing our customers with the highest quality PCBs, exceptional service, and competitive pricing.

We are committed to continuous improvement and innovation, and we are always looking for ways to better serve our customers and stay ahead of the competition.

The following is a list of the services and products.