Benefits of Using Rigid Flex PCBs

Rigid flex PCBs, or printed circuit boards, have become increasingly popular in the electronics industry due to their numerous benefits and advantages.

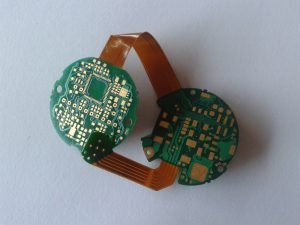

These innovative PCBs combine the flexibility of flexible circuits with the durability of rigid boards, making them ideal for a wide range of applications.

In this article, we will explore the basics of rigid flex PCB production and discuss the benefits of using these advanced circuit boards.

Rigid flex PCBs are manufactured using a combination of rigid and flexible materials, allowing for greater design flexibility and versatility.

The production process begins with the creation of the rigid portion of the board, which is typically made from fiberglass or other rigid substrates.

This rigid section provides stability and support for the components mounted on the board.

Next, the flexible portion of the board is created using flexible materials such as polyimide.

This flexible section allows the PCB to bend and conform to the shape of the device or application it is being used in.

The flexible portion is then laminated to the rigid section, creating a single, integrated circuit board that combines the best of both worlds.

One of the key benefits of using rigid flex PCBs is their ability to reduce the overall size and weight of electronic devices.

By eliminating the need for bulky connectors and cables, rigid flex PCBs can help streamline the design of electronic devices and make them more compact and lightweight. This can be especially beneficial in applications where space is limited or weight is a concern.

In addition to their compact size, rigid flex PCBs also offer improved reliability and durability compared to traditional PCBs.

The integrated design of rigid flex boards reduces the number of interconnects and solder joints, which can help minimize the risk of mechanical failures and signal integrity issues. This can result in a more reliable and robust electronic device that is less prone to failure or malfunction.

Another advantage of using rigid flex PCBs is their ability to withstand harsh environmental conditions.

The combination of rigid and flexible materials allows these circuit boards to bend and flex without compromising their structural integrity.

This makes them ideal for applications where the PCB may be subjected to vibration, shock, or extreme temperatures.

Furthermore, rigid flex PCBs can help simplify the assembly process and reduce overall production costs.

By combining multiple PCBs into a single, integrated design, manufacturers can streamline the assembly process and reduce the number of components and connectors needed. This can help lower production costs and improve overall efficiency.

Overall, rigid flex PCBs offer a wide range of benefits and advantages that make them an attractive choice for a variety of electronic applications.

From their compact size and lightweight design to their improved reliability and durability, rigid flex PCBs are a versatile and innovative solution for modern electronics.

By understanding the basics of rigid flex PCB production and the benefits of using these advanced circuit boards, manufacturers can take advantage of this cutting-edge technology to create more efficient and reliable electronic devices.