Benefits of Ultra-Thin, High-Density Interconnects in Avionics Miniaturization

In the world of avionics, where every ounce of weight and inch of space matters, the demand for ultra-thin, high-density interconnects has never been greater.

These advanced technologies are revolutionizing the way electronic components are integrated into aircraft systems, allowing for significant reductions in size and weight without sacrificing performance or reliability.

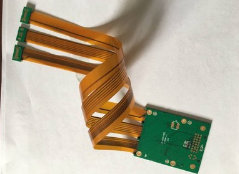

Flex-rigid PCBs, in particular, have emerged as a key enabler of avionics miniaturization.

These innovative circuit boards combine the flexibility of traditional flexible circuits with the durability and reliability of rigid boards, making them ideal for applications where space is at a premium.

By allowing for complex, high-density interconnects in a compact form factor, flex-rigid PCBs are helping to drive the development of smaller, lighter, and more efficient avionics systems.

One of the primary benefits of ultra-thin, high-density interconnects in avionics is the ability to reduce the overall size and weight of electronic components.

By using flex-rigid PCBs to create compact, tightly integrated circuits, designers can achieve significant space savings compared to traditional rigid boards.

This not only allows for more efficient use of available space within the aircraft, but also helps to reduce the overall weight of the avionics system, leading to improved fuel efficiency and performance.

In addition to size and weight savings, ultra-thin, high-density interconnects offer improved signal integrity and reliability.

The tight spacing of traces and vias on flex-rigid PCBs minimizes signal loss and crosstalk, resulting in better overall performance for the avionics system.

Furthermore, the use of high-quality materials and advanced manufacturing techniques ensures that these interconnects are highly durable and resistant to environmental factors such as temperature fluctuations, humidity, and vibration, making them well-suited for the demanding conditions of aerospace applications.

Another key advantage of ultra-thin, high-density interconnects in avionics is the ability to simplify assembly and reduce overall system complexity.

By integrating multiple functions onto a single flex-rigid PCB, designers can eliminate the need for additional interconnects and connectors, reducing the number of components and potential points of failure in the system.

This not only streamlines the manufacturing process but also improves overall system reliability and maintenance, leading to lower lifecycle costs for the aircraft operator.

Furthermore, the use of flex-rigid PCBs in avionics enables greater design flexibility and customization.

With the ability to create complex, multi-layered circuits in a compact form factor, designers have the freedom to optimize the layout of electronic components for maximum efficiency and performance.

This level of customization allows for the development of highly tailored avionics systems that meet the specific requirements of each aircraft platform, leading to improved functionality and overall system performance.

In conclusion, ultra-thin, high-density interconnects, particularly in the form of flex-rigid PCBs, are playing a crucial role in enabling avionics miniaturization.

By offering size and weight savings, improved signal integrity and reliability, simplified assembly, and greater design flexibility,

these advanced technologies are helping to drive the development of smaller, lighter, and more efficient avionics systems for the aerospace industry.

As the demand for more compact and powerful electronic components continues to grow, the importance of ultra-thin, high-density interconnects in avionics will only continue to increase, shaping the future of aircraft electronics for years to come.