Benefits of Flex Rigid PCBs in Modern Technology Industry

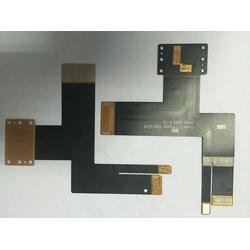

Flex rigid PCBs, or flexible printed circuit boards, have revolutionized the technology industry in recent years. These innovative circuit boards offer a unique combination of flexibility and rigidity, making them ideal for a wide range of applications in modern electronics. From smartphones and wearables to medical devices and automotive systems, flex rigid PCBs have become an essential component in the design and manufacturing of cutting-edge technology products.

One of the key benefits of flex rigid PCBs is their ability to reduce the size and weight of electronic devices. Traditional rigid PCBs are limited by their fixed shape and size, which can be a significant constraint in the design of compact and lightweight products. Flex rigid PCBs, on the other hand, can be bent, twisted, and folded to fit into tight spaces and conform to the shape of the device. This flexibility allows designers to create smaller and more streamlined products without sacrificing functionality or performance.

In addition to their compact size, flex rigid PCBs also offer improved reliability and durability compared to traditional rigid PCBs. The flexible sections of the circuit board are less prone to mechanical stress and vibration, reducing the risk of solder joint failures and other common issues that can occur in harsh operating environments. This increased reliability is particularly important in critical applications such as medical devices and aerospace systems, where the failure of a single component can have serious consequences.

Another advantage of flex rigid PCBs is their ability to simplify the assembly process and reduce manufacturing costs. Traditional rigid PCBs often require multiple separate boards and connectors to achieve the desired functionality, leading to complex and time-consuming assembly processes. Flex rigid PCBs, on the other hand, can integrate multiple functions into a single board, reducing the number of components and connections needed. This streamlined design not only saves time and labor during assembly but also reduces the risk of errors and defects that can occur when assembling multiple boards.

Furthermore, flex rigid PCBs offer improved signal integrity and electrical performance compared to traditional rigid PCBs. The flexible sections of the circuit board can be used to route high-speed signals with minimal impedance and crosstalk, ensuring reliable communication between components and reducing the risk of signal degradation. This enhanced electrical performance is essential for applications such as high-speed data transmission, where even small signal losses can have a significant impact on system performance.

Overall, the impact of flex rigid PCBs on the technology industry has been profound. These innovative circuit boards have enabled designers to create smaller, lighter, and more reliable products while simplifying the manufacturing process and improving electrical performance. As technology continues to evolve and demand for compact and high-performance devices grows, flex rigid PCBs are likely to play an increasingly important role in shaping the future of electronics. Whether in consumer electronics, medical devices, or industrial systems, flex rigid PCBs are transforming the way we think about circuit board design and manufacturing.