Topology-Optimized Lightweight Rigid-Flex for Hypersonic Vehicle Structures

Topology-optimized lightweight rigid-flex designs are revolutionizing the structural integrity of hypersonic vehicles. As the aerospace industry pushes the boundaries of speed and performance, engineers face unique challenges in developing materials that can withstand extreme conditions without compromising structural strength. By employing topology optimization techniques, designers are able to create intricate structures that prioritize both weight reduction and durability.

Understanding the Need for Lightweight Structures in Hypersonic Travel

Hypersonic vehicles travel at speeds greater than five times the speed of sound, generating immense aerodynamic forces and thermal stresses. Traditional materials often fall short under these extreme conditions, necessitating a focus on lightweight solutions. Lightweight structures not only enhance speed and fuel efficiency but also improve overall performance and maneuverability.

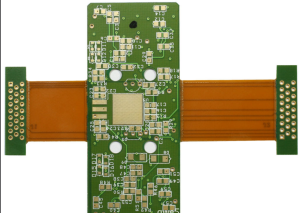

In this context, rigid-flex configurations play a crucial role. These hybrid designs integrate rigid and flexible components to create a system that can adapt to dynamic loading conditions while maintaining structural integrity. The result is a vehicle that can withstand the rigors of hypersonic travel while optimizing weight.

The Role of Topology Optimization in Structural Design

Topology optimization is a computational design process that allows engineers to determine the best material layout within a given design space, respecting specified load conditions and constraints. By applying this process, it is possible to create lightweight structures that are tailored specifically for their intended use.

The benefits of employing topology optimization in rigid-flex design include:

- Material Efficiency: By identifying optimal areas where material can be reduced without sacrificing strength, engineers can significantly decrease the overall weight of the structure.

- Enhanced Performance: Lightweight designs reduce the needed thrust, leading to improved fuel efficiency and increased speed, which are crucial factors in hypersonic travel.

- Adaptability: Topology-optimized structures can be fine-tuned for various applications, making them suitable for different flight regimes and environmental conditions.

Integration of Rigid-Flex Components

The unique attributes of rigid-flex structures allow them to maintain performance across various load conditions. By combining rigid sections that provide stability and flexible segments that can absorb shock and accommodate movement, designers maximize the adaptability of hypersonic vehicles. This integration hinges on several key factors:

Material Selection

Choosing the right materials is critical in achieving optimal performance. Advanced composites, such as carbon fiber reinforced polymers (CFRP), are often utilized due to their exceptional strength-to-weight ratios. These materials not only reduce weight but also enhance durability, making them ideal for hypersonic applications where high temperatures and pressures are prevalent.

Structural Analysis

Performing comprehensive structural analyses using finite element methods (FEM) enables engineers to predict how different design configurations will behave under hypersonic conditions. This step is crucial in refining the topology-optimized models and ensuring that they meet safety and performance standards.

Prototyping and Testing

While simulations and design software are invaluable, building prototypes for real-world testing is equally essential. Physical testing allows engineers to observe how the rigid-flex components perform under actual flight conditions, providing insights that virtual simulations may overlook. Iterative testing helps refine the design for maximum efficiency and functionality.

Future Prospects in Hypersonic Vehicle Design

The advancement of topology-optimized lightweight rigid-flex structures marks a significant milestone in the future of hypersonic travel. As the technology continues to evolve, the potential for new applications expands beyond military and space exploration to commercial sectors, including faster air travel.

Moreover, ongoing research is likely to showcase innovative materials and techniques that further enhance the capabilities of hypersonic vehicles. Integrating artificial intelligence in the design process could optimize structures based on real-time data, advancing the agility and responsiveness of these vehicles.

Conclusion

As the aerospace sector increasingly embraces the potential of hypersonic travel, topology-optimized lightweight rigid-flex designs will undoubtedly play a centerpiece role in future developments. The ability to reduce weight while enhancing structural integrity poses a significant advantage in an industry where every ounce counts. By leveraging the principles of topology optimization, engineers are not only paving the way for faster travel but also ensuring that safety remains paramount in the pursuit of speed and performance.

In approaching the complexities of hypersonic vehicle structures with innovative design methods, the aerospace community is well positioned to overcome current limitations and explore uncharted territories in aviation and beyond.