Benefits of Using Rigid Flex PCBs in Electronic Devices

Printed circuit boards (PCBs) are an essential component in electronic devices, providing the necessary connections between various electronic components. While traditional rigid PCBs have been widely used in the industry, rigid flex PCBs are gaining popularity due to their versatility and ability to meet the demands of modern electronic devices. In this article, we will explore the benefits of using rigid flex PCBs in electronic devices and the various applications where they excel.

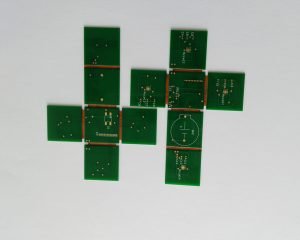

One of the key advantages of rigid flex PCBs is their flexibility, which allows them to be bent or folded to fit into tight spaces or irregular shapes.

This flexibility makes them ideal for use in devices with complex designs or limited space, such as smartphones, wearables, and medical devices.

By eliminating the need for multiple rigid PCBs and connectors, rigid flex PCBs can reduce the overall size and weight of the device, while also improving reliability by minimizing the number of interconnects.

In addition to their flexibility, rigid flex PCBs offer improved reliability and durability compared to traditional rigid PCBs.

The combination of rigid and flexible layers in a single board reduces the risk of mechanical failures, such as solder joint cracks or broken traces, that can occur in devices subjected to vibration or thermal cycling. This increased reliability is crucial for applications where downtime is not an option, such as aerospace, automotive, and industrial electronics.

Furthermore, rigid flex PCBs can simplify the assembly process and reduce manufacturing costs by eliminating the need for additional connectors and cables. By integrating multiple PCBs into a single rigid flex board, manufacturers can streamline the assembly process, reduce the number of components, and minimize the risk of assembly errors. This not only saves time and labor costs but also improves the overall quality and consistency of the final product.

Another benefit of using rigid flex PCBs is their ability to withstand harsh environmental conditions, such as high temperatures, humidity, and chemical exposure. The combination of rigid and flexible materials in a single board provides a high level of protection against moisture and contaminants, making them suitable for use in outdoor or industrial applications. Additionally, rigid flex PCBs can be designed to meet specific requirements for temperature resistance, flame retardancy, and chemical compatibility, ensuring reliable performance in even the most demanding environments.

In conclusion, the versatility of rigid flex PCBs makes them an ideal choice for a wide range of electronic devices and applications.

Their flexibility, reliability, durability, and cost-effectiveness make them a preferred option for manufacturers looking to optimize the performance and efficiency of their products. Whether used in smartphones, wearables, medical devices, aerospace, automotive, or industrial electronics, rigid flex PCBs offer numerous benefits that can help companies stay ahead of the competition and meet the evolving demands of the market.