Benefits of Flex PCB Assembly in Automotive Applications

Flex PCB assembly plays a crucial role in the automotive industry, providing numerous benefits that help improve the performance, reliability,

and efficiency of vehicles. In this article, we will explore the advantages of using flex PCB assembly in automotive applications.

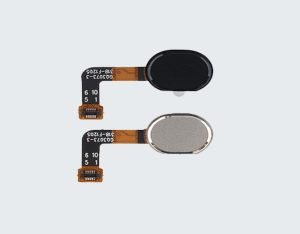

One of the key benefits of flex PCB assembly in the automotive industry is its ability to reduce space and weight. Flex PCBs are much thinner and lighter than traditional rigid PCBs, allowing for more compact and lightweight designs in vehicles. This is particularly important in modern vehicles, where space is at a premium and every ounce counts. By using flex PCB assembly, automotive manufacturers can save valuable space and weight, leading to more efficient and fuel-efficient vehicles.

Another advantage of flex PCB assembly in automotive applications is its flexibility and durability. Flex PCBs can be bent, twisted, and folded to fit into tight spaces and conform to the shape of the vehicle. This flexibility allows for more creative and innovative designs, leading to improved performance and functionality. Additionally, flex PCBs are more resistant to vibration, shock, and temperature fluctuations, making them ideal for the harsh operating conditions of automotive environments. This increased durability helps to extend the lifespan of the vehicle and reduce maintenance costs over time.

Furthermore, flex PCB assembly offers improved signal integrity and reliability in automotive applications. Flex PCBs have shorter signal paths and fewer interconnects, reducing the risk of signal loss, interference, and crosstalk. This results in better performance and more reliable operation of electronic systems in vehicles. Additionally, flex PCBs can be designed with controlled impedance and signal integrity features, further enhancing the quality of the electrical connections in automotive applications. This improved signal integrity helps to ensure the safety and functionality of critical systems in vehicles, such as airbags, ABS brakes, and engine control units.

In addition to these benefits, flex PCB assembly also offers cost savings and faster time-to-market for automotive manufacturers.

Flex PCBs can be manufactured in high volumes using automated assembly processes, leading to lower production costs and faster turnaround times.

This allows automotive manufacturers to bring new products to market more quickly and cost-effectively, giving them a competitive edge in the industry. Furthermore, the flexibility and versatility of flex PCB assembly make it easier to design and prototype new electronic systems for vehicles, reducing development time and costs.

Overall, the role of flex PCB assembly in the automotive industry is essential for improving the performance, reliability, and efficiency of vehicles.

By reducing space and weight, increasing flexibility and durability, improving signal integrity and reliability, and offering cost savings and faster time-to-market, flex PCB assembly provides numerous benefits that help automotive manufacturers stay ahead of the competition. As technology continues to advance and vehicles become more complex, the importance of flex PCB assembly in automotive applications will only continue to grow.