Benefits of Using Rigid Flex PCBs in Electronics Manufacturing

In the ever-evolving world of electronics manufacturing, the demand for more compact, lightweight, and durable electronic devices continues to grow.

As a result, manufacturers are constantly seeking innovative solutions to meet these demands. One such solution that has gained popularity in recent years is the use of rigid flex PCBs.

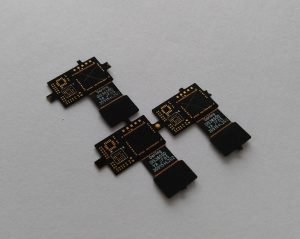

Rigid flex PCBs combine the best of both rigid and flexible PCBs, offering a unique combination of flexibility and durability.

These boards consist of a combination of rigid and flexible layers, allowing for greater design flexibility and reliability. This innovative technology has revolutionized the way electronic devices are designed and manufactured, offering a wide range of benefits to manufacturers and end-users alike.

One of the key benefits of using rigid flex PCBs in electronics manufacturing is their ability to reduce the overall size and weight of electronic devices.

By combining rigid and flexible layers into a single board, manufacturers can create more compact and lightweight devices without sacrificing performance or reliability. This is particularly important in industries such as aerospace, automotive, and medical devices, where space and weight constraints are critical factors.

Additionally, rigid flex PCBs offer greater design flexibility compared to traditional rigid PCBs. The flexible layers allow for more complex and intricate designs, enabling manufacturers to create devices with unique shapes and configurations. This flexibility also allows for more efficient use of space within the device, leading to improved performance and functionality.

Another significant benefit of using rigid flex PCBs is their enhanced durability and reliability. The combination of rigid and flexible layers provides greater resistance to mechanical stress, vibration, and thermal cycling, making these boards ideal for applications where reliability is paramount. This increased durability also leads to longer product lifecycles, reducing the need for frequent repairs and replacements.

Furthermore, rigid flex PCBs offer improved signal integrity and reduced electromagnetic interference (EMI) compared to traditional PCBs.

The flexible layers act as a shield, protecting sensitive components from external interference and ensuring reliable signal transmission.

This is particularly important in high-speed and high-frequency applications, where signal integrity is critical to the overall performance of the device.

In addition to these technical benefits, rigid flex PCBs also offer cost savings for manufacturers. While the initial cost of manufacturing rigid flex PCBs may be higher than traditional PCBs, the overall cost savings over the product lifecycle can be significant. The increased durability and reliability of rigid flex PCBs lead to fewer warranty claims and repairs, reducing overall maintenance costs for manufacturers.

Overall, the rise of rigid flex PCBs has been a game-changer in electronics manufacturing, offering a wide range of benefits to manufacturers and end-users alike. From reduced size and weight to improved durability and reliability, these innovative boards have revolutionized the way electronic devices are designed and manufactured. As the demand for more compact, lightweight, and reliable electronic devices continues to grow, rigid flex PCBs are poised to play a key role in shaping the future of electronics manufacturing.