Benefits of Using Rigid Flex PCBs in IoT Devices

The manufacturing process of rigid flex PCBs plays a crucial role in the development of IoT devices.

These devices require a high level of reliability and durability to withstand the harsh environments they may be exposed to.

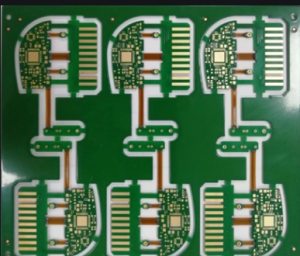

Rigid flex PCBs offer a unique solution by combining the benefits of both rigid and flexible PCBs, allowing for greater design flexibility and reliability.

One of the key benefits of using rigid flex PCBs in IoT devices is their ability to reduce the overall size and weight of the device.

By combining the rigid and flexible portions of the PCB, designers can create more compact and lightweight devices without sacrificing functionality.

This is particularly important in IoT applications where space is often limited and weight can impact performance.

In addition to size and weight savings, rigid flex PCBs also offer improved reliability compared to traditional PCBs.

The combination of rigid and flexible materials allows for better distribution of stress and strain, reducing the likelihood of mechanical failures.

This is especially important in IoT devices that may be subject to vibration, shock, and temperature fluctuations.

The manufacturing process of rigid flex PCBs involves several key steps that must be carefully executed to ensure the highest quality and reliability.

One of the first steps in the process is designing the PCB layout to optimize the placement of rigid and flexible sections.

This requires a thorough understanding of the device’s requirements and constraints to ensure that the PCB meets all necessary specifications.

Once the layout is finalized, the next step is to fabricate the rigid and flexible portions of the PCB separately.

The rigid portions are typically made using traditional PCB manufacturing techniques, while the flexible portions are created using specialized materials and processes.

These two portions are then combined using advanced lamination techniques to create a single, integrated PCB.

During the manufacturing process, it is important to pay close attention to quality control measures to ensure that the final product meets all necessary standards.

This includes conducting thorough inspections and tests at each stage of the process to identify any potential issues or defects.

By catching problems early on, manufacturers can avoid costly rework and ensure that the final product meets all necessary specifications.

In conclusion, the manufacturing process of rigid flex PCBs is a critical step in the development of IoT devices.

By combining the benefits of rigid and flexible PCBs, designers can create more compact, lightweight, and reliable devices that are well-suited for a wide range of applications.

By following best practices and paying close attention to quality control measures, manufacturers can ensure that their rigid flex PCBs meet the highest standards of quality and reliability.