Advancements in Rigid Flex PCB Design

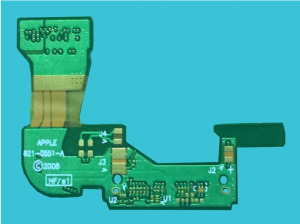

Rigid flex PCB assembly has become increasingly popular in the electronics industry due to its ability to combine the benefits of both rigid and flexible PCBs. This innovative technology allows for greater design flexibility, reduced space requirements, and improved reliability.

As technology continues to evolve, so do the trends in rigid flex PCB assembly.

One of the latest trends in rigid flex PCB assembly is the use of advanced materials.

Manufacturers are constantly seeking out new materials that offer improved performance and reliability.

High-performance materials such as polyimide and liquid crystal polymer are being used to create rigid flex PCBs that can withstand harsh environments and extreme temperatures. These materials also offer better signal integrity and impedance control, making them ideal for high-speed applications.

Another trend in rigid flex PCB assembly is the miniaturization of components.

As electronic devices become smaller and more compact, the demand for smaller and more densely packed PCBs has increased.

Manufacturers are now able to produce rigid flex PCBs with smaller vias, finer traces, and tighter spacing between components.

This trend has led to the development of advanced manufacturing techniques such as laser drilling and microvia technology,

which allow for the creation of highly complex and compact PCB designs.

In addition to advanced materials and miniaturization, the use of automation in rigid flex PCB assembly is also on the rise.

Automation allows for faster and more precise assembly processes, resulting in higher quality and more reliable PCBs.

Automated equipment such as pick-and-place machines, solder paste printers, and reflow ovens are now commonly

used in rigid flex PCB assembly to streamline production and reduce human error.

Furthermore, the integration of smart technologies in rigid flex PCB assembly is another emerging trend.

Smart technologies such as RFID tags, sensors, and embedded systems are being incorporated into rigid flex PCBs

to enable advanced functionalities such as real-time monitoring, data logging, and remote control.

These smart features are revolutionizing the way electronic devices are designed and manufactured, opening up new possibilities for innovation and customization.

As the demand for smaller, more reliable, and more advanced electronic devices continues to grow, the trends in

rigid flex PCB assembly are expected to evolve even further. Manufacturers will continue to push the boundaries of technology by exploring

new materials, refining manufacturing processes, and integrating smart technologies into their designs. The future of rigid flex PCB assembly is bright, with endless possibilities for innovation and advancement.

In conclusion, the latest trends in rigid flex PCB assembly are driven by the need for improved performance, reliability, and functionality

in electronic devices. Advanced materials, miniaturization, automation, and smart technologies are shaping the future of rigid flex PCB assembly,

allowing manufacturers to create highly complex and compact PCB designs that meet the demands of today’s technology-driven world.

As technology continues to evolve, so too will the trends in rigid flex PCB assembly, paving the way for even more exciting developments in the field.