Advancements in Rigid Flex PCB Materials

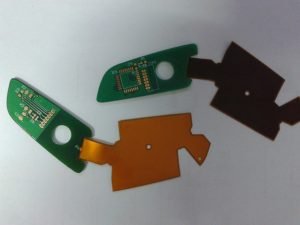

Rigid flex PCBs have become increasingly popular in the electronics industry due to their ability to combine the benefits of both rigid and flexible PCBs.

These boards are made up of a combination of rigid and flexible materials, allowing for greater design flexibility and reliability. As technology continues to advance, so do the materials used in rigid flex PCB manufacturing.

One of the latest innovations in rigid flex PCB materials is the use of high-performance laminates. These laminates are designed to withstand high temperatures and provide excellent electrical performance. They are also more resistant to moisture and chemicals, making them ideal for harsh environments. High-performance laminates are essential for ensuring the reliability and longevity of rigid flex PCBs.

Another advancement in rigid flex PCB materials is the use of thinner and lighter materials. Thinner materials allow for more compact designs, while lighter materials reduce the overall weight of the PCB. This is particularly important in applications where weight and space are critical factors. By using thinner and lighter materials, manufacturers can create more efficient and cost-effective rigid flex PCBs.

In addition to high-performance laminates and thinner materials, manufacturers are also exploring the use of new materials such as liquid crystal polymers (LCP) and polyimide. These materials offer excellent thermal stability, chemical resistance, and flexibility, making them ideal for rigid flex PCB applications. LCP, in particular, is known for its low moisture absorption and high dielectric strength, making it a popular choice for high-frequency applications.

Furthermore, advancements in material technology have led to the development of flexible substrates with improved mechanical properties.

These substrates are more durable and resistant to bending and flexing, ensuring the reliability of rigid flex PCBs in dynamic applications.

By using flexible substrates with enhanced mechanical properties, manufacturers can create rigid flex PCBs that can withstand the rigors of everyday use.

Overall, the latest innovations in rigid flex PCB materials are focused on improving performance, reliability, and flexibility. By using high-performance laminates, thinner and lighter materials, new materials such as LCP and polyimide, and flexible substrates with improved mechanical properties, manufacturers can create rigid flex PCBs that meet the demands of modern electronics applications. These advancements in material technology are driving the evolution of rigid flex PCB manufacturing, allowing for more innovative and reliable designs.

In conclusion, the latest innovations in rigid flex PCB materials are revolutionizing the electronics industry. By using advanced materials such as high-performance laminates, thinner and lighter materials, new materials like LCP and polyimide, and flexible substrates with improved mechanical properties, manufacturers can create rigid flex PCBs that are more reliable, flexible, and efficient. These advancements in material technology are shaping the future of rigid flex PCB manufacturing, paving the way for more advanced and sophisticated electronics applications.