The Integration of Rigid-Flex PCBs in Autonomous Vehicles

The Integration of Rigid-Flex PCBs in Autonomous Vehicles

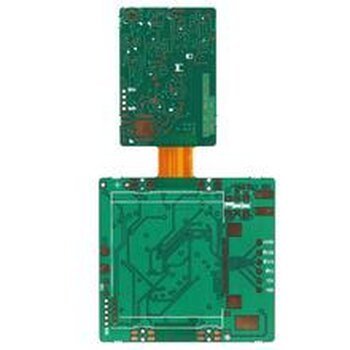

Autonomous vehicles represent one of the most transformative applications of Artificial Intelligence of Things (AIoT) technology. These vehicles rely on a complex network of sensors, processors, and communication systems to navigate, make decisions, and interact with their environment. Rigid-flex printed circuit boards (PCBs) are playing a critical role in enabling the development of autonomous vehicles by providing the durability, flexibility, and high-performance connectivity needed to support these advanced systems.

1. Enabling Advanced Sensor Integration

Autonomous vehicles rely on a wide array of sensors, including LiDAR, radar, cameras, and ultrasonic sensors, to perceive their surroundings. Rigid-flex PCBs enable the seamless integration of these sensors into the vehicle’s design, ensuring reliable and accurate data collection.

Applications:

- LiDAR Systems: Rigid-flex PCBs support the integration of LiDAR sensors, which use laser pulses to create detailed 3D maps of the environment.

- Camera Modules: In camera systems, rigid-flex PCBs enable high-resolution imaging and real-time data processing, essential for object detection and recognition.

2. Supporting High-Speed Data Processing

Autonomous vehicles require powerful computing capabilities to process the vast amounts of data generated by their sensors and make real-time decisions. Rigid-flex PCBs provide the platform for integrating high-performance processors and memory modules.

Applications:

- AI Processors: Rigid-flex PCBs enable the integration of AI processors that can analyze sensor data and make driving decisions in real time.

- Edge Computing: By supporting edge computing capabilities, rigid-flex PCBs allow autonomous vehicles to process data locally, reducing latency and improving response times.

3. Enhancing Communication Systems

Autonomous vehicles rely on robust communication systems to interact with other vehicles, infrastructure, and cloud platforms. Rigid-flex PCBs enable the integration of advanced communication modules, such as 5G and V2X (vehicle-to-everything) technology.

Applications:

- 5G Connectivity: Rigid-flex PCBs support the integration of 5G modules, enabling high-speed communication and low-latency data transmission.

- V2X Systems: In V2X systems, rigid-flex PCBs facilitate communication between vehicles and infrastructure, improving safety and traffic management.

4. Ensuring Durability in Harsh Environments

Autonomous vehicles operate in demanding environments, where they may be exposed to vibrations, temperature fluctuations, and moisture. Rigid-flex PCBs are designed to withstand these conditions, ensuring reliable operation.

Applications:

- Under-the-Hood Electronics: Rigid-flex PCBs used in engine control units and other under-the-hood applications provide the durability needed to withstand high temperatures and vibrations.

- Outdoor Sensors: In sensors mounted on the exterior of the vehicle, rigid-flex PCBs ensure reliable performance despite exposure to weather conditions.

5. Facilitating Compact and Lightweight Designs

The design of autonomous vehicles requires the integration of numerous electronic components into a compact and lightweight form factor. Rigid-flex PCBs enable the development of space-efficient designs that maximize functionality while minimizing weight.

Applications:

- In-Cabin Electronics: Rigid-flex PCBs enable the integration of infotainment systems, climate control units, and other in-cabin electronics into sleek and ergonomic designs.

- Sensor Arrays: In sensor arrays, rigid-flex PCBs allow for the compact integration of multiple sensors, reducing the overall size and weight of the vehicle.

6. Supporting Redundancy and Fail-Safe Systems

Safety is a top priority in autonomous vehicles, and redundancy is essential to ensure reliable operation. Rigid-flex PCBs enable the integration of redundant systems and fail-safe mechanisms, ensuring that the vehicle can continue to operate safely in the event of a failure.

Applications:

- Redundant Sensor Systems: Rigid-flex PCBs support the integration of redundant sensors, ensuring that the vehicle can continue to perceive its environment even if one sensor fails.

- Fail-Safe Control Systems: In control systems, rigid-flex PCBs enable the integration of fail-safe mechanisms that can take over in the event of a system failure.

7. Driving Innovation in Autonomous Vehicle Technology

Rigid-flex PCBs are driving innovation in autonomous vehicle technology by enabling the development of new features and capabilities. For example, the integration of AI algorithms and advanced communication systems is becoming increasingly feasible with the capabilities of rigid-flex PCBs.

Applications:

- AI-Driven Navigation: Rigid-flex PCBs enable the integration of AI algorithms that can analyze sensor data and make real-time navigation decisions.

- Advanced Driver Assistance Systems (ADAS): In ADAS, rigid-flex PCBs support features such as adaptive cruise control, lane-keeping assist, and automatic emergency braking.

Conclusion

Rigid-flex PCBs are playing a transformative role in the development of autonomous vehicles, enabling the integration of advanced sensors, high-speed data processing, robust communication systems, and fail-safe mechanisms. By ensuring durability, facilitating compact and lightweight designs, and driving innovation, rigid-flex PCBs are helping to create safer, more efficient, and more reliable autonomous vehicles. As the demand for autonomous vehicles continues to grow, rigid-flex PCBs will remain at the forefront of technological innovation, empowering the next generation of transportation solutions.