The Benefits of Implementing Quality Control Measures in Rigid Flex PCB Assembly

Quality control is a critical aspect of any manufacturing process, and this holds true for rigid flex PCB assembly as well.

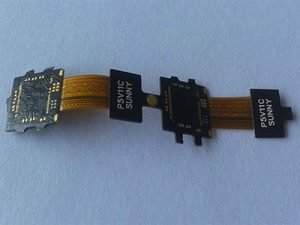

Rigid flex PCBs are a combination of rigid and flexible circuit boards, offering a unique solution for electronic devices that require

both flexibility and durability. Ensuring the quality of these complex boards is essential to guarantee the reliability and performance of the final product.

One of the key benefits of implementing quality control measures in rigid flex PCB assembly is the prevention of defects.

Defects in PCBs can lead to malfunctions, performance issues, and even safety hazards in electronic devices. By conducting thorough inspections and tests at each stage of the assembly process, manufacturers can identify and rectify any potential issues before they escalate into larger problems.

Another advantage of quality control in rigid flex PCB assembly is the improvement of overall product quality.

By maintaining strict quality standards, manufacturers can produce PCBs that meet or exceed industry specifications and customer expectations.

This not only enhances the reputation of the company but also increases customer satisfaction and loyalty.

Furthermore, quality control measures can help reduce production costs in the long run. By detecting and addressing defects early on, manufacturers can avoid costly rework, scrap, and warranty claims. This leads to higher efficiency, lower manufacturing expenses, and ultimately, increased profitability for the company.

In addition to preventing defects and improving product quality, quality control in rigid flex PCB assembly also plays a crucial role in ensuring compliance with industry regulations and standards. Many industries, such as aerospace, medical, and automotive, have strict requirements for electronic components, including PCBs. By adhering to these standards, manufacturers can demonstrate their commitment to quality and safety, gaining the trust of customers and regulatory bodies alike.

Moreover, quality control measures can help identify areas for process improvement and innovation. By analyzing data from inspections and tests, manufacturers can pinpoint weaknesses in their assembly process and implement corrective actions to enhance efficiency and productivity. This continuous improvement mindset not only benefits the company but also drives technological advancements in the field of rigid flex PCB assembly.

Overall, the importance of quality control in rigid flex PCB assembly cannot be overstated. From preventing defects and improving product quality to reducing costs and ensuring compliance with industry standards, quality control measures are essential for the success of any manufacturing operation. By investing in quality control, manufacturers can enhance their reputation, increase customer satisfaction, and drive innovation in the ever-evolving world of electronic manufacturing.