The Benefits of Implementing Quality Control Measures in Rigid Flex Assembly

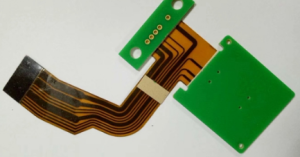

Quality control is a critical aspect of any manufacturing process, and this is especially true in the realm of rigid flex assembly. Rigid flex assemblies are complex systems that combine rigid and flexible circuit boards, making them susceptible to a variety of issues that can impact their performance and reliability. Implementing quality control measures in the assembly process is essential to ensuring that these assemblies meet the highest standards of quality and reliability.

One of the key benefits of implementing quality control measures in rigid flex assembly is the ability to identify and address potential issues early in the manufacturing process. By conducting thorough inspections and tests at each stage of assembly, manufacturers can catch any defects or inconsistencies before they have a chance to impact the final product. This proactive approach not only helps to prevent costly rework and delays but also ensures that the finished assemblies meet the required specifications and performance standards.

In addition to preventing defects, quality control measures can also help to improve the overall efficiency of the assembly process. By identifying and addressing issues early on, manufacturers can streamline their production processes and reduce the likelihood of errors or rework. This can lead to faster turnaround times, lower production costs, and ultimately, higher customer satisfaction.

Another important benefit of quality control in rigid flex assembly is the ability to maintain consistency and repeatability in the manufacturing process. By establishing clear quality standards and procedures, manufacturers can ensure that each assembly is produced to the same high level of quality, regardless of who is working on the line. This consistency is essential for meeting customer expectations and building a reputation for reliability and excellence in the industry.

Furthermore, quality control measures can help to enhance the overall reliability and performance of rigid flex assemblies. By conducting rigorous testing and inspections, manufacturers can identify any potential weaknesses or vulnerabilities in the design or construction of the assemblies and make the necessary adjustments to improve their durability and longevity. This can help to reduce the likelihood of failures or malfunctions in the field, ultimately leading to greater customer satisfaction and loyalty.

In conclusion, quality control is a critical aspect of rigid flex assembly that should not be overlooked. By implementing thorough inspections, tests, and procedures at each stage of the manufacturing process, manufacturers can prevent defects, improve efficiency, maintain consistency, and enhance the reliability and performance of their assemblies. Ultimately, investing in quality control measures can help manufacturers to deliver products that meet the highest standards of quality and reliability, ensuring customer satisfaction and success in the competitive marketplace.