The Impact of Rigid-Flex PCBs on Wearable AIoT Devices

The Impact of Rigid-Flex PCBs on Wearable AIoT Devices

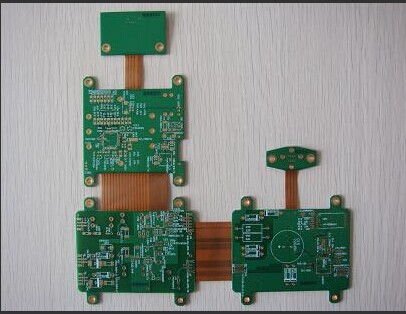

Wearable devices have become a cornerstone of the Artificial Intelligence of Things (AIoT), enabling users to monitor their health, stay connected, and interact with their environment in innovative ways. At the heart of these devices are rigid-flex printed circuit boards (PCBs), which combine the durability of rigid boards with the flexibility of flexible circuits. This unique combination has revolutionized the design and functionality of wearable AIoT devices, making them smaller, more reliable, and more versatile than ever before.

Compact and Lightweight Design

One of the most significant impacts of rigid-flex PCBs on wearable AIoT devices is their ability to enable compact and lightweight designs. Wearable devices, such as smartwatches, fitness trackers, and medical monitors, need to be small and comfortable to wear. Rigid-flex PCBs allow designers to create three-dimensional layouts that maximize space efficiency, integrating multiple components into a sleek and ergonomic design. For example, in a smartwatch, rigid-flex PCBs enable the integration of sensors, processors, and communication modules without compromising on size or weight. This miniaturization enhances the user experience, making wearable devices more practical and appealing.

Enhanced Durability and Reliability

Wearable devices are subjected to constant movement, bending, and twisting, which can put significant stress on their internal components. Rigid-flex PCBs are designed to withstand these conditions, making them ideal for wearable applications. The flexible portions of the PCB can bend and twist without breaking, while the rigid sections provide structural support for critical components. This durability ensures long-term reliability, reducing the need for maintenance and replacement. For instance, in fitness trackers, rigid-flex PCBs can endure the rigors of daily use, such as running and cycling, ensuring uninterrupted operation and accurate data collection.

Seamless Integration of AI and IoT Components

Wearable AIoT devices rely on the seamless integration of AI algorithms and IoT connectivity. Rigid-flex PCBs facilitate this integration by providing a reliable platform for mounting high-performance components such as microprocessors, memory modules, and wireless communication chips. The ability to route signals efficiently across both rigid and flexible sections minimizes signal loss and electromagnetic interference, ensuring optimal performance. In smart glasses, for example, rigid-flex PCBs enable real-time data processing and transmission, allowing users to access augmented reality (AR) content with minimal latency.

Enabling Advanced Functionality

The versatility of rigid-flex PCBs enables the development of wearable AIoT devices with advanced functionality. For example, in medical wearables, rigid-flex PCBs are used to integrate sensors that monitor vital signs, such as heart rate, blood pressure, and glucose levels. These devices can transmit data to healthcare providers in real time, enabling remote monitoring and timely interventions. The compact design and biocompatibility of rigid-flex PCBs make them ideal for implantable devices, such as pacemakers and neurostimulators, which require reliable and long-lasting performance.

In addition to healthcare, rigid-flex PCBs are driving innovation in other wearable applications. For instance, in industrial settings, wearable devices equipped with rigid-flex PCBs can monitor workers’ health and safety, detecting hazardous conditions and alerting them to potential risks. In sports and fitness, rigid-flex PCBs enable the development of advanced performance monitors that track metrics such as speed, distance, and calorie burn, helping athletes optimize their training.

Driving Innovation in Wearable Technology

As wearable technology continues to evolve, the demand for rigid-flex PCBs is expected to grow. Manufacturers are investing in advanced materials and manufacturing techniques, such as laser drilling and additive manufacturing, to meet the increasing complexity of wearable AIoT devices. Additionally, the development of eco-friendly rigid-flex PCBs aligns with the growing emphasis on sustainability in technology. By enabling smaller, smarter, and more reliable devices, rigid-flex PCBs are driving innovation in the wearable AIoT landscape and paving the way for a more connected and intelligent future.

Conclusion

Rigid-flex PCBs are playing a transformative role in the development of wearable AIoT devices. Their unique combination of flexibility, durability, and performance makes them indispensable for applications ranging from consumer electronics to healthcare. As wearable technology continues to advance, the impact of rigid-flex PCBs will only grow, empowering smarter and more efficient devices that enhance the way we live, work, and interact with our environment.