The Benefits of Nanotechnology in Improving Rigid-Flex PCB Performance

Nanotechnology has revolutionized the field of electronics, particularly in the development of rigid-flex PCBs.

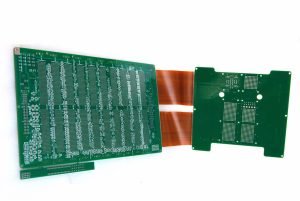

These innovative circuit boards combine the flexibility of flexible PCBs with the durability of rigid PCBs, making them ideal for a wide range of applications.

The integration of nanotechnology into the manufacturing process of rigid-flex PCBs has further enhanced their performance and reliability.

One of the key benefits of nanotechnology in rigid-flex PCBs is the improved electrical conductivity.

Nanomaterials, such as silver nanoparticles, have significantly higher conductivity compared to traditional materials.

By incorporating these nanomaterials into the conductive traces of the PCB, the resistance is reduced, leading to faster signal transmission and lower power consumption.

This results in improved overall performance of the PCB, making it more efficient and reliable.

In addition to enhanced conductivity, nanotechnology also offers improved thermal management in rigid-flex PCBs.

Nanomaterials have high thermal conductivity, which allows for better heat dissipation from the components on the board. This helps prevent overheating and ensures the longevity of the PCB.

By incorporating nanomaterials into the dielectric layers of the PCB, heat can be efficiently transferred away from sensitive components, reducing the risk of thermal damage.

Furthermore, nanotechnology has enabled the development of nanocoatings for rigid-flex PCBs.

These coatings provide a protective barrier against environmental factors such as moisture, dust, and chemicals.

By applying nanocoatings to the PCB, the risk of corrosion and short circuits is minimized, increasing the reliability and lifespan of the board.

Additionally, nanocoatings can also improve the mechanical strength of the PCB, making it more resistant to bending and flexing.

Another advantage of nanotechnology in rigid-flex PCBs is the miniaturization of components.

Nanomaterials allow for the fabrication of smaller and more compact components, leading to higher component density on the board.

This results in a reduction in the size and weight of the PCB, making it ideal for applications where space is limited.

The increased component density also improves the overall performance of the PCB by reducing signal interference and improving signal integrity.

Overall, the integration of nanotechnology into the manufacturing process of rigid-flex PCBs has had a significant impact on their performance and reliability.

From improved electrical conductivity and thermal management to enhanced protection and miniaturization, nanotechnology offers a wide range of benefits for rigid-flex PCBs.

As technology continues to advance, we can expect to see even more innovations in the field of nanotechnology and its application in electronics.

Nanotechnology has truly transformed the way we design and manufacture rigid-flex PCBs, paving the way for more efficient and reliable electronic devices.