Benefits of Rigid Flex PCBs in Modern Electronics Manufacturing

In the ever-evolving world of electronics manufacturing, rigid flex PCBs have emerged as a game-changer.

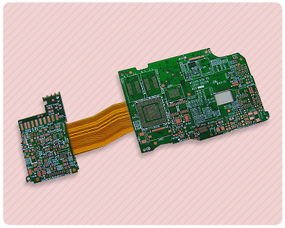

These innovative circuit boards combine the benefits of both rigid and flexible PCBs, offering a unique solution for a wide range of applications.

As technology continues to advance, the demand for more compact, lightweight, and durable electronic devices is on the rise.

Rigid flex PCBs are well-positioned to meet these demands, making them a key player in the future of the industry.

One of the primary benefits of rigid flex PCBs is their ability to reduce the overall size and weight of electronic devices.

By combining rigid and flexible sections into a single board, designers can create more compact and lightweight products without sacrificing functionality.

This is particularly important in industries such as aerospace, automotive, and medical devices, where space and weight constraints are critical considerations.

Another key advantage of rigid flex PCBs is their enhanced durability and reliability. Traditional PCBs are prone to damage from bending, twisting, and vibration,

which can lead to premature failure of the electronic device. Rigid flex PCBs, on the other hand, are designed to withstand these types of stresses, making them ideal for applications where reliability is paramount.

This increased durability not only extends the lifespan of the device but also reduces the need for costly repairs and replacements.

In addition to their size, weight, and durability benefits, rigid flex PCBs also offer improved signal integrity and EMI/RFI shielding.

The rigid sections of the board provide a stable platform for high-speed signals, while the flexible sections allow for greater design flexibility and reduced signal loss.

This results in better overall performance and reliability of the electronic device. Furthermore, the combination of rigid and flexible materials in a single board helps to

minimize electromagnetic interference and radio frequency interference, ensuring that the device operates smoothly in a variety of environments.

As the demand for smaller, lighter, and more reliable electronic devices continues to grow, the future of the rigid flex PCB and assembly industry looks bright.

Manufacturers are investing in new technologies and processes to meet the evolving needs of the market, driving innovation and pushing the boundaries of what is possible.

From wearable technology to IoT devices to medical implants, rigid flex PCBs are poised to play a key role in shaping the future of electronics manufacturing.

In conclusion, the benefits of rigid flex PCBs in modern electronics manufacturing are clear. These innovative circuit boards offer a unique combination of size, weight, durability,

and performance advantages that make them an attractive choice for a wide range of applications. As technology continues to advance, the demand for smaller, lighter, and more reliable electronic

devices will only continue to grow, further solidifying the position of rigid flex PCBs as a key player in the industry. With their ability to meet the evolving needs of the market and drive innovation,

rigid flex PCBs are well-positioned to shape the future of electronics manufacturing for years to come.