Emerging Technologies in Flex PCB Assembly

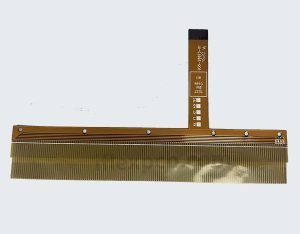

Flex PCB assembly has come a long way since its inception, with continuous innovations and developments shaping the future of this technology.

As the demand for flexible printed circuit boards (PCBs) continues to rise in various industries such as automotive, aerospace, and consumer electronics, manufacturers are constantly striving to improve the efficiency and reliability of flex PCB assembly processes.

One of the key innovations in flex PCB assembly is the use of advanced materials that offer enhanced flexibility and durability.

Traditional rigid PCB materials are not suitable for flexible applications due to their inability to bend and twist without breaking.

However, with the introduction of materials such as polyimide and liquid crystal polymer (LCP), manufacturers can now create flexible

PCBs that can withstand the rigors of bending and flexing without compromising performance.

In addition to advanced materials, advancements in manufacturing techniques have also played a crucial role in the evolution of flex PCB assembly.

Traditional PCB assembly processes involve the use of rigid substrates and through-hole components, which are not suitable for flexible applications. However, with the development of flexible surface mount technology (SMT) and laser drilling techniques, manufacturers can now assemble components directly onto flexible substrates, eliminating the need for through-hole components and improving the overall flexibility of the PCB.

Furthermore, the integration of automation and robotics in flex PCB assembly has revolutionized the manufacturing process, allowing for faster production speeds and higher levels of precision. Automated pick-and-place machines can now accurately place components onto flexible substrates with minimal human intervention, reducing the risk of errors and improving overall product quality.

Another key development in flex PCB assembly is the miniaturization of components, which has enabled manufacturers to create smaller and more compact flexible PCBs. With the increasing demand for wearable devices and IoT applications, the ability to create smaller and more lightweight PCBs is essential for meeting the needs of modern consumers.

Moreover, advancements in 3D printing technology have also had a significant impact on flex PCB assembly.

3D printing allows manufacturers to create complex and intricate designs that would be impossible to achieve using traditional manufacturing methods.

This has opened up new possibilities for creating custom-designed flexible PCBs that are tailored to specific applications and requirements.

Looking ahead, the future of flex PCB assembly is bright, with continued innovations and developments on the horizon.

As the demand for flexible electronics continues to grow, manufacturers will need to adapt and evolve their processes to meet the needs of the market.

By embracing new materials, manufacturing techniques, and technologies, manufacturers can stay ahead of the curve and continue to push the boundaries of what is possible with flex PCB assembly.

In conclusion, the future of flex PCB assembly is filled with exciting possibilities, as manufacturers continue to innovate and develop new technologies to meet the demands of the ever-evolving electronics industry. With advancements in materials, manufacturing techniques, automation, and 3D printing, the potential for creating flexible PCBs that are smaller, lighter, and more durable than ever before is within reach. As we look towards the future, it is clear that flex PCB assembly will play a crucial role in shaping the next generation of electronic devices and technologies.