Benefits of Rigid Flex PCBs in Circuit Design

In the ever-evolving world of technology, circuit design plays a crucial role in the development of electronic devices.

As the demand for smaller, more efficient devices continues to grow, designers are constantly seeking new ways to optimize their designs.

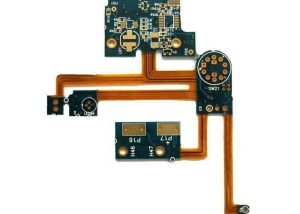

One emerging trend in circuit design is the use of rigid flex PCBs, which offer a range of benefits over traditional rigid PCBs.

Rigid flex PCBs combine the best of both worlds by incorporating rigid and flexible circuitry into a single board.

This unique design allows for greater flexibility in layout and packaging, making it ideal for applications where space is limited.

By eliminating the need for connectors and cables, rigid flex PCBs can reduce the overall size and weight of a device, while also improving reliability and signal integrity.

One of the key benefits of rigid flex PCBs is their ability to withstand harsh environments.

Traditional rigid PCBs are prone to damage from vibration, shock, and temperature fluctuations, which can lead to premature failure.

Rigid flex PCBs, on the other hand, are more durable and reliable, making them well-suited for applications in industries such as aerospace, automotive, and medical devices.

Another advantage of rigid flex PCBs is their cost-effectiveness.

While the initial investment may be higher than traditional rigid PCBs, the overall savings in terms of reduced assembly time, lower material costs, and increased reliability can make rigid flex PCBs a more economical choice in the long run. Additionally, the flexibility of rigid flex PCBs allows for more efficient use of space, which can lead to further cost savings in terms of reduced board size and complexity.

In addition to their durability and cost-effectiveness, rigid flex PCBs also offer improved signal integrity.

The flexible portions of the board can be used to route high-speed signals, reducing signal loss and interference.

This can result in better performance and reliability for electronic devices, especially those with complex or high-speed circuitry.

Furthermore, rigid flex PCBs can simplify the assembly process by reducing the number of components and connections required.

This can lead to faster production times and lower labor costs, making rigid flex PCBs an attractive option for manufacturers looking to streamline their operations. Additionally, the reduced number of interconnects can improve overall system reliability by minimizing points of failure.

Overall, the future of circuit design looks bright with the emergence of rigid flex PCBs.

These innovative boards offer a range of benefits over traditional rigid PCBs, including increased durability, cost-effectiveness, improved signal integrity, and simplified assembly. As technology continues to advance, rigid flex PCBs are likely to become an increasingly popular choice for designers looking to optimize their designs and create more efficient electronic devices.