The Benefits of Using Rigid Flex PCBs in Electronic Devices

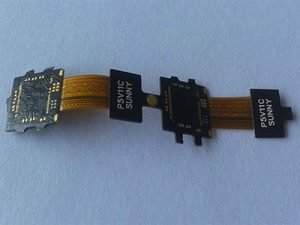

Rigid-flex PCBs have become increasingly popular in the electronics industry due to their ability to combine the benefits of both rigid and flexible PCBs.

These innovative circuit boards are designed to be more durable and reliable than traditional PCBs, making them ideal for use in a wide range of electronic devices. The evolution of rigid-flex PCB manufacturing techniques has played a crucial role in the development of these advanced circuit boards.

One of the key benefits of using rigid-flex PCBs in electronic devices is their ability to reduce the overall size and weight of the device.

By combining rigid and flexible sections in a single board, designers can create more compact and lightweight devices without sacrificing functionality.

This is particularly important in industries such as aerospace, where space and weight constraints are critical considerations.

In addition to their compact size, rigid-flex PCBs also offer improved reliability and durability compared to traditional PCBs.

The flexible sections of the board are designed to withstand bending and flexing without compromising the integrity of the circuitry.

This makes rigid-flex PCBs ideal for use in devices that are subject to vibration, shock, or other forms of mechanical stress.

The evolution of rigid-flex PCB manufacturing techniques has led to significant advancements in the design and production of these circuit boards.

Early rigid-flex PCBs were limited in terms of complexity and reliability, but recent innovations have made it possible to create highly complex and reliable rigid-flex designs. This has opened up new possibilities for designers looking to push the boundaries of what is possible in electronic device design.

One of the key advancements in rigid-flex PCB manufacturing techniques is the development of advanced materials that are specifically designed for use in these circuit boards. These materials are chosen for their ability to withstand the rigors of flexible and rigid sections, as well as their compatibility with modern manufacturing processes. By using these advanced materials, designers can create rigid-flex PCBs that are more reliable and durable than ever before.

Another important advancement in rigid-flex PCB manufacturing techniques is the use of advanced manufacturing processes such as laser drilling and additive manufacturing. These processes allow for greater precision and control in the creation of complex rigid-flex designs, resulting in circuit boards that are more reliable and efficient. By leveraging these advanced manufacturing techniques, designers can create rigid-flex PCBs that meet the demanding requirements of modern electronic devices.

Overall, the evolution of rigid-flex PCB manufacturing techniques has revolutionized the electronics industry by providing designers with a versatile and reliable solution for creating compact, lightweight, and durable electronic devices. By combining the benefits of rigid and flexible PCBs, rigid-flex PCBs offer a unique set of advantages that make them ideal for a wide range of applications. As technology continues to advance, we can expect to see even more innovations in rigid-flex PCB manufacturing techniques, further expanding the possibilities for electronic device design.