Increased Flexibility

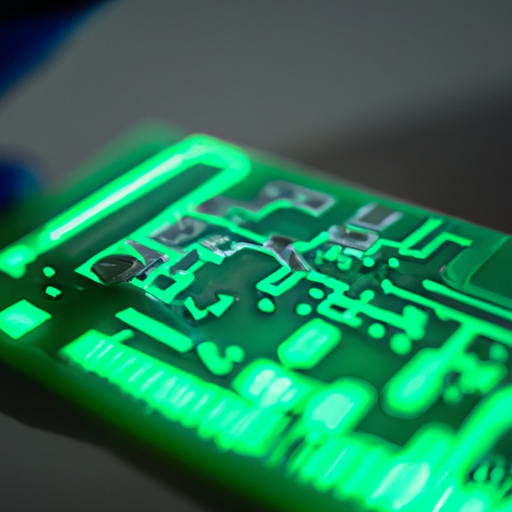

Flex PCBs, or flexible printed circuit boards, have become increasingly popular in electronic assembly due to their numerous benefits.

One of the key advantages of using flex PCBs is their increased flexibility compared to traditional rigid PCBs.

This flexibility allows for greater design freedom and the ability to create more compact and lightweight electronic devices.

Flex PCBs are made from flexible substrate materials such as polyimide or polyester, which can bend and twist without breaking.

This flexibility makes them ideal for applications where space is limited or where the PCB needs to conform to a specific shape or contour.

For example, flex PCBs are commonly used in wearable devices, medical implants, and automotive electronics where a rigid PCB would be impractical.

In addition to their physical flexibility, flex PCBs also offer greater electrical flexibility.

The ability to bend and twist the PCB allows for more complex routing of traces and components,

leading to improved signal integrity and reduced electromagnetic interference.

This can result in better performance and reliability of the electronic device.

Another benefit of using flex PCBs is their durability.

Traditional rigid PCBs are prone to cracking and breaking when subjected to repeated bending or vibration,

whereas flex PCBs are designed to withstand these types of mechanical stresses.

This makes them ideal for applications where the electronic device will be subjected to harsh environments or constant movement.

Furthermore, flex PCBs are often more cost-effective than rigid PCBs in certain applications.

The ability to create more compact and lightweight designs can lead to savings in materials and manufacturing costs. Additionally, the flexibility of flex PCBs can reduce the need for additional connectors and cables, further lowering the overall cost of the electronic assembly.

One of the key considerations when using flex PCBs is the need for specialized assembly techniques.

Flex PCBs require careful handling during assembly to prevent damage to the flexible substrate and components. This may require additional training for assembly technicians and investment in specialized equipment such as flexible soldering fixtures.

Despite these challenges, the benefits of using flex PCBs in electronic assembly far outweigh the drawbacks.

The increased flexibility, durability, and cost-effectiveness of flex PCBs make them an attractive option for a wide range of applications.

As technology continues to evolve, the demand for flexible and lightweight electronic devices will only continue to grow, making flex PCBs an essential component in the electronics industry.

In conclusion, the benefits of using flex PCBs in electronic assembly are clear.

Their increased flexibility, durability, and cost-effectiveness make them an ideal choice for a wide range of applications.

As technology advances and the demand for more compact and lightweight electronic devices grows, flex PCBs will continue to play a crucial role in shaping the future of electronics.