Improved Durability and Reliability

Minimally invasive surgical tools have revolutionized the field of medicine by allowing for less invasive procedures, shorter recovery times, and reduced risk of complications for patients.

One crucial component of these tools is the printed circuit board (PCB), which serves as the backbone for the electronic components that control the tool’s functions.

In recent years, rigid-flex PCBs have emerged as a popular choice for use in minimally invasive surgical tools due to their numerous benefits, including improved durability and reliability.

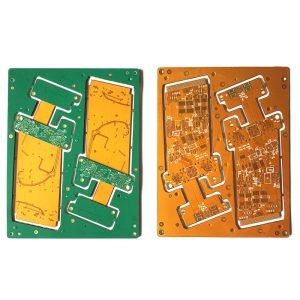

Rigid-flex PCBs are a hybrid of traditional rigid PCBs and flexible PCBs, combining the best of both worlds to create a versatile and robust solution for electronic applications.

The rigid sections provide stability and support for components, while the flexible sections allow for greater flexibility in design and integration into complex assemblies.

This unique combination makes rigid-flex PCBs ideal for use in minimally invasive surgical tools, where space is limited and reliability is paramount.

One of the key benefits of using rigid-flex PCBs in minimally invasive surgical tools is their improved durability.

Traditional rigid PCBs are prone to damage from bending, twisting, and vibration, which can lead to premature failure of the electronic components. In contrast, rigid-flex PCBs are designed to withstand the rigors of the operating room environment, with the flexible sections providing a buffer against mechanical stress and strain. This increased durability ensures that the surgical tool will continue to function reliably throughout its lifespan, reducing the need for costly repairs or replacements.

In addition to improved durability, rigid-flex PCBs also offer enhanced reliability in minimally invasive surgical tools.

The flexible sections of the PCB allow for greater freedom in design, enabling engineers to create more compact and efficient layouts that minimize the risk of signal interference or crosstalk.

This improved signal integrity ensures that the electronic components in the surgical tool will operate as intended, providing precise control and feedback to the surgeon during procedures.

Furthermore, rigid-flex PCBs are less prone to solder joint fatigue and other common failure modes, resulting in a more reliable and long-lasting solution for critical medical applications.

The use of rigid-flex PCBs in minimally invasive surgical tools also offers benefits in terms of cost and time savings.

By integrating multiple functions onto a single PCB, engineers can reduce the overall size and complexity of the tool, leading to lower manufacturing costs and faster assembly times.

This streamlined approach not only saves money for medical device manufacturers but also allows for quicker turnaround times and more efficient production processes.

Additionally, the increased reliability of rigid-flex PCBs means that surgical tools will require less frequent maintenance and calibration, further reducing costs and downtime for healthcare providers.

Overall, the benefits of using rigid-flex PCBs in minimally invasive surgical tools are clear.

Improved durability, reliability, and cost savings make these advanced PCBs an ideal choice for critical medical applications where precision and performance are paramount.

As technology continues to advance, we can expect to see even greater innovations in the field of rigid-flex PCBs, further enhancing the capabilities of minimally invasive surgical tools and improving outcomes for patients around the world.