Improved Reliability

Rigid-flex assembly technology has become increasingly popular in high-reliability applications due to its numerous benefits.

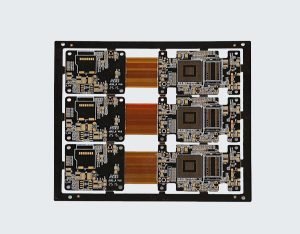

This innovative technology combines the flexibility of flexible circuits with the rigidity of traditional printed circuit boards, resulting in a solution that offers improved reliability, durability, and performance.

In this article, we will explore the key benefits of rigid-flex assembly technology for high-reliability applications.

One of the primary advantages of rigid-flex assembly technology is its ability to reduce the number of interconnects and solder joints in a system. Traditional PCBs require multiple interconnects and solder joints to connect different components, which can increase the risk of failure due to mechanical stress, vibration, and thermal cycling.

Rigid-flex assemblies, on the other hand, eliminate the need for many of these interconnects by integrating flexible circuits directly into the rigid PCB, resulting in a more robust and reliable solution.

Another benefit of rigid-flex assembly technology is its ability to reduce the overall size and weight of a system.

By combining the flexibility of flexible circuits with the compactness of rigid PCBs, designers can create smaller and lighter assemblies that are ideal for space-constrained applications.

This can be particularly advantageous in industries such as aerospace, medical devices, and automotive, where size and weight are critical factors.

In addition to improved reliability and reduced size and weight, rigid-flex assembly technology also offers enhanced signal integrity and electrical performance.

The integration of flexible circuits into the rigid PCB allows for shorter signal paths, reduced electromagnetic interference, and improved impedance control, resulting in better signal quality and overall system performance.

This is especially important in high-speed and high-frequency applications where signal integrity is paramount.

Furthermore, rigid-flex assemblies are highly resistant to environmental factors such as moisture, dust, and temperature fluctuations.

The combination of rigid and flexible materials in a single assembly creates a robust and durable solution that can withstand harsh operating conditions without compromising performance.

This makes rigid-flex technology ideal for applications that require high reliability and longevity, such as military and aerospace systems.

Overall, the benefits of rigid-flex assembly technology for high-reliability applications are clear.

From improved reliability and durability to reduced size and weight, enhanced signal integrity, and resistance to environmental factors, rigid-flex assemblies offer a comprehensive solution for demanding applications. As technology continues to advance and the need for reliable and high-performance systems grows, rigid-flex assembly technology will undoubtedly play a crucial role in meeting these requirements.

By leveraging the advantages of rigid-flex technology, designers can create innovative and reliable solutions that push the boundaries of what is possible in high-reliability applications.