Improved Reliability

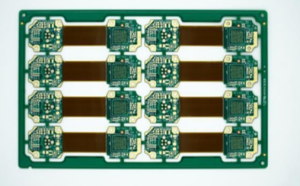

Rigid-flex PCBs, or printed circuit boards, have become increasingly popular in the electronics industry due to their numerous advantages over traditional rigid PCBs. One of the key benefits of using rigid-flex PCBs is their improved reliability. In this article, we will explore how the unique design of rigid-flex PCBs contributes to their reliability and why they are a preferred choice for many electronic devices.

One of the main reasons why rigid-flex PCBs are more reliable than traditional rigid PCBs is their ability to withstand mechanical stress.

The flexible sections of a rigid-flex PCB are made of polyimide, a highly durable and flexible material that can bend and twist without breaking.

This flexibility allows rigid-flex PCBs to be used in applications where traditional rigid PCBs would be prone to failure, such as in devices that need to be folded or bent.

Additionally, the combination of rigid and flexible sections in a rigid-flex PCB helps to reduce the number of interconnects needed in a device.

This means that there are fewer points of potential failure, leading to a more reliable overall system.The rigid sections of the PCB provide stability and support for components, while the flexible sections allow for greater design flexibility and the ability to fit into tight spaces.

Furthermore, rigid-flex PCBs are less susceptible to vibration and shock, making them ideal for use in applications where the device may be subject to rough handling or extreme conditions. The flexible sections of the PCB act as shock absorbers, helping to protect the components from damage.

This increased durability and resistance to mechanical stress make rigid-flex PCBs a reliable choice for a wide range of electronic devices.

In addition to their mechanical reliability, rigid-flex PCBs also offer improved electrical reliability.

The use of flexible materials in the PCB design helps to reduce signal interference and crosstalk, leading to better signal integrity and overall performance.

This is especially important in high-speed applications where signal quality is critical.

Another advantage of using rigid-flex PCBs is their ability to reduce the overall size and weight of a device.

By combining the functionality of both rigid and flexible PCBs into a single design, manufacturers can create more compact and lightweight devices.

This is particularly beneficial for portable electronics, where space and weight are at a premium.

Overall, the improved reliability of rigid-flex PCBs makes them a preferred choice for many electronic devices.

Their ability to withstand mechanical stress, reduce points of failure, and improve signal integrity make them a reliable and durable option for a wide range of applications. Whether used in consumer electronics, medical devices, or industrial equipment, rigid-flex PCBs offer numerous advantages that can help to improve the performance and longevity of electronic devices.