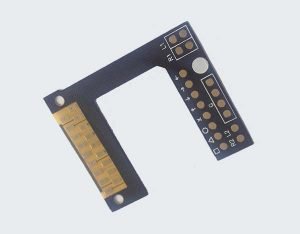

Importance of Testing and Inspection Techniques for Rigid Flex PCBs

Rigid flex PCBs are a crucial component in many electronic devices, providing a combination of flexibility and durability that traditional rigid PCBs cannot match. These boards are used in a wide range of applications, from medical devices to aerospace technology, making their reliability and performance essential.

To ensure that rigid flex PCBs meet the highest standards of quality, testing and inspection techniques are crucial.

One of the most common testing techniques for rigid flex PCBs is electrical testing.

This involves checking the conductivity of the board to ensure that all connections are functioning properly. Electrical testing can help identify any shorts, opens, or other defects that could affect the performance of the PCB.

By using specialized equipment such as flying probe testers or automated test equipment, manufacturers can quickly and accurately test the electrical integrity of rigid flex PCBs.

In addition to electrical testing, manufacturers also use visual inspection techniques to ensure the quality of rigid flex PCBs.

Visual inspection involves examining the board for any physical defects, such as solder bridges, misaligned components, or damaged traces.

By using magnification tools and automated optical inspection systems, manufacturers can identify even the smallest defects that could impact the functionality of the PCB.

Another important testing technique for rigid flex PCBs is thermal testing.

Thermal testing involves subjecting the board to extreme temperatures to simulate real-world operating conditions.

By testing the PCB’s performance under different temperature conditions, manufacturers can ensure that it will function reliably in a variety of environments. Thermal testing can help identify any weak points in the board’s design or materials that could lead to failure under certain conditions.

In addition to these testing techniques, manufacturers also use environmental testing to ensure the reliability of rigid flex PCBs.

Environmental testing involves subjecting the board to various environmental conditions, such as humidity, vibration, and shock, to simulate the challenges it may face in the field.

By testing the PCB’s performance under these conditions, manufacturers can identify any weaknesses in the design or materials that could lead to failure in the field.

Overall, testing and inspection techniques are essential for ensuring the quality and reliability of rigid flex PCBs.

By using a combination of electrical testing, visual inspection, thermal testing, and environmental testing, manufacturers can identify and address any defects or weaknesses in the board before it is deployed in a product.

These techniques help to ensure that rigid flex PCBs meet the highest standards of quality and performance, making them a reliable choice for a wide range of applications.

In conclusion, testing and inspection techniques play a crucial role in ensuring the quality and reliability of rigid flex PCBs.

By using a combination of electrical testing, visual inspection, thermal testing, and environmental testing, manufacturers can identify and address any defects or weaknesses in the board before it is deployed in a product.

These techniques help to ensure that rigid flex PCBs meet the highest standards of quality and performance, making them an essential component in many electronic devices.