Advancements in Sustainable Materials for Rigid-Flex PCB Production

In recent years, there has been a growing emphasis on sustainability in the electronics industry, particularly in the production of printed circuit boards (PCBs).

As the demand for smaller, lighter, and more flexible electronic devices continues to rise, manufacturers are looking for ways to reduce their environmental impact and improve the overall sustainability of their products. One area where significant progress has been made is in the development of sustainable materials for rigid-flex PCB production.

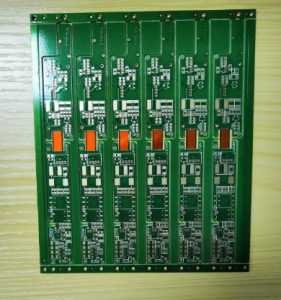

Rigid-flex PCBs are a type of circuit board that combines both rigid and flexible materials, allowing for greater design flexibility and improved performance in a variety of applications.

Traditionally, these boards have been made using materials such as fiberglass, copper, and epoxy resins, which can be harmful to the environment and difficult to recycle.

However, in recent years, there has been a shift towards the use of more sustainable materials in the production of rigid-flex PCBs.

One of the most promising developments in this area is the use of bio-based materials, such as bioplastics and bioresins, which are derived from renewable sources such as corn, sugarcane, and wood pulp.

These materials offer a more environmentally friendly alternative to traditional petroleum-based plastics and resins, and can help reduce the carbon footprint of PCB production.

In addition to being more sustainable, bio-based materials also offer other benefits, such as improved flexibility, durability, and thermal performance, making them an attractive option for manufacturers looking to improve the overall quality of their products.

Another area of innovation in sustainable materials for rigid-flex PCB production is the use of recycled materials, such as recycled plastics and metals.

By incorporating recycled materials into the production process, manufacturers can reduce the amount of waste generated during manufacturing and help conserve valuable natural resources.

In addition to being more environmentally friendly, recycled materials can also help reduce production costs and improve the overall efficiency of the manufacturing process.

In addition to bio-based and recycled materials, manufacturers are also exploring the use of alternative materials, such as nanomaterials and conductive inks, in the production of rigid-flex PCBs.

These materials offer unique properties, such as improved conductivity, thermal stability, and mechanical strength, which can help enhance the performance and reliability of electronic devices.

While these materials are still in the early stages of development, they show great promise for the future of sustainable PCB production.

Looking ahead to 2025, it is clear that sustainable materials will play an increasingly important role in the production of rigid-flex PCBs.

As consumer demand for eco-friendly products continues to grow, manufacturers will need to prioritize sustainability in their production processes in order to remain competitive in the market.

By investing in the development of sustainable materials and technologies, manufacturers can not only reduce their environmental impact but also improve the overall quality and performance of their products.

In conclusion, the use of sustainable materials in rigid-flex PCB production is a key trend to watch in the coming years.

By incorporating bio-based, recycled, and alternative materials into their production processes, manufacturers can reduce their environmental impact, improve the quality of their products, and meet the growing demand for eco-friendly electronics. As technology continues to evolve, it is essential for manufacturers to stay ahead of the curve and embrace sustainable materials as a key driver of innovation in the electronics industry.