Sustainable Manufacturing of Rigid-Flex PCBs for AIoT

Sustainable Manufacturing of Rigid-Flex PCBs for AIoT

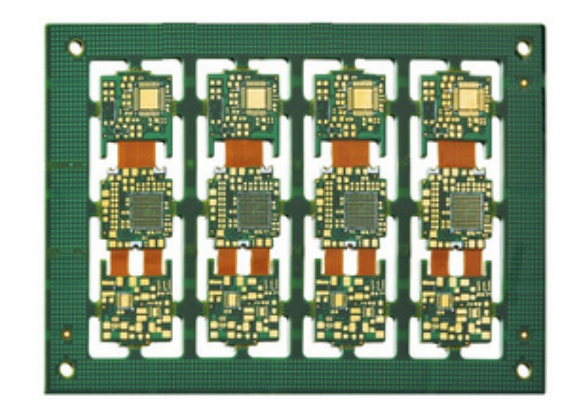

As the demand for Artificial Intelligence of Things (AIoT) devices continues to grow, so does the need for sustainable manufacturing practices. Rigid-flex printed circuit boards (PCBs), which are essential components of AIoT devices, are no exception. The electronics industry is increasingly focusing on reducing its environmental impact, and sustainable manufacturing of rigid-flex PCBs is becoming a key priority. By adopting eco-friendly materials, energy-efficient processes, and waste-reduction strategies, manufacturers are ensuring that rigid-flex PCBs meet the performance requirements of AIoT while minimizing their environmental footprint.

1. Eco-Friendly Materials

The choice of materials used in rigid-flex PCB manufacturing has a significant impact on sustainability. Traditional materials, such as halogenated flame retardants and lead-based solders, can be harmful to the environment. Manufacturers are now turning to eco-friendly alternatives that reduce toxicity and improve recyclability.

Innovations:

- Lead-Free Solders: Lead-free solders, such as those based on tin-silver-copper (SAC) alloys, are replacing traditional lead-based solders, reducing environmental and health risks.

- Biodegradable Substrates: Materials like polylactic acid (PLA) and other biodegradable polymers are being explored as alternatives to traditional PCB substrates.

- Recyclable Laminates: High-performance laminates made from recyclable materials are being developed to reduce waste and improve the end-of-life recyclability of rigid-flex PCBs.

2. Energy-Efficient Manufacturing Processes

Energy consumption is a major concern in PCB manufacturing. Sustainable practices focus on reducing energy usage through advanced technologies and process optimization.

Innovations:

- Additive Manufacturing: 3D printing and other additive manufacturing techniques reduce material waste and energy consumption compared to traditional subtractive methods.

- Laser Direct Imaging (LDI): LDI technology improves precision and reduces the energy required for photolithography processes.

- Renewable Energy: Manufacturers are increasingly powering their facilities with renewable energy sources, such as solar and wind, to reduce their carbon footprint.

3. Waste Reduction and Recycling

The production of rigid-flex PCBs generates waste, including scrap materials, chemicals, and water. Sustainable manufacturing practices aim to minimize waste and promote recycling.

Innovations:

- Closed-Loop Water Systems: These systems recycle water used in manufacturing processes, reducing water consumption and minimizing wastewater discharge.

- Chemical Recycling: Advanced chemical recycling techniques are being developed to recover valuable materials from PCB waste, such as copper and gold.

- Scrap Material Reuse: Scrap materials from PCB production are being repurposed for other applications, reducing overall waste.

4. Green Design Practices

Sustainable manufacturing begins at the design stage. By incorporating green design principles, engineers can create rigid-flex PCBs that are easier to recycle and have a lower environmental impact.

Innovations:

- Modular Design: Modular PCBs allow for easier disassembly and recycling of individual components at the end of their lifecycle.

- Minimalist Design: Reducing the number of layers and components in a PCB design minimizes material usage and waste.

- Design for Disassembly: Engineers are designing PCBs with disassembly in mind, using screws and clips instead of adhesives to make recycling easier.

5. Compliance with Environmental Standards

Adhering to environmental regulations and standards is a key aspect of sustainable manufacturing. Rigid-flex PCB manufacturers are ensuring compliance with global standards to reduce their environmental impact.

Standards:

- RoHS (Restriction of Hazardous Substances): This directive restricts the use of hazardous materials, such as lead and mercury, in electronic products.

- REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): This regulation ensures the safe use of chemicals in manufacturing processes.

- ISO 14001: This international standard provides a framework for environmental management systems, helping manufacturers reduce their environmental impact.

6. Lifecycle Assessment and Circular Economy

Sustainable manufacturing of rigid-flex PCBs involves considering the entire lifecycle of the product, from raw material extraction to end-of-life disposal. The goal is to create a circular economy where materials are reused and recycled rather than discarded.

Innovations:

- Lifecycle Assessment (LCA): LCA tools are used to evaluate the environmental impact of rigid-flex PCBs at every stage of their lifecycle, helping manufacturers identify areas for improvement.

- Take-Back Programs: Some manufacturers are implementing take-back programs to collect and recycle end-of-life PCBs, reducing electronic waste.

- Material Recovery: Advanced techniques are being developed to recover valuable materials from discarded PCBs, such as copper, gold, and rare earth metals.

7. Collaboration for Sustainability

Achieving sustainable manufacturing requires collaboration across the supply chain, from raw material suppliers to end-users. Manufacturers are working closely with partners to develop and implement sustainable practices.

Initiatives:

- Supplier Partnerships: Collaborating with suppliers to source eco-friendly materials and reduce the environmental impact of the supply chain.

- Industry Alliances: Joining industry alliances and initiatives, such as the Responsible Business Alliance (RBA), to promote sustainability in electronics manufacturing.

- Customer Engagement: Educating customers about the benefits of sustainable PCBs and encouraging them to adopt eco-friendly practices.

Conclusion

Sustainable manufacturing of rigid-flex PCBs is essential for reducing the environmental impact of AIoT devices. By adopting eco-friendly materials, energy-efficient processes, waste-reduction strategies, green design practices, and lifecycle assessment tools, manufacturers are ensuring that rigid-flex PCBs meet the performance requirements of AIoT while minimizing their environmental footprint. As the demand for AIoT devices continues to grow, sustainable manufacturing practices will play a critical role in creating a greener and more sustainable future.