Sustainability in the Rigid-Flex PCB Process: Adopting Green Chemistry and Reduced Waste Techniques

Sustainability in the rigid-flex PCB process is increasingly becoming a priority in the electronics manufacturing industry.

As environmental concerns grow, companies are seeking ways to minimize their ecological impact while still meeting production demands.

Rigorous flex printed circuit boards (PCBs) are known for their versatile applications in various technology sectors, including consumer electronics, automotive, and medical devices.

Thus, integrating sustainable practices into their production can lead to significant positive outcomes for both the environment and manufacturers.

Understanding Rigid-Flex PCBs

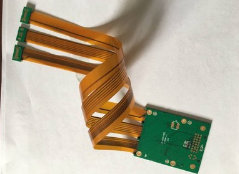

Rigid-flex PCBs combine the best features of both rigid and flexible circuit boards, allowing for compact and lightweight designs.

This makes them ideal for applications where space is limited, such as in smartphones or medical devices.

However, traditional manufacturing processes for these boards often involve toxic chemicals and generate substantial waste, which poses challenges for sustainability.

The Need for Sustainability

As the demand for electronic products increases, so does the pressure on manufacturers to adopt more sustainable practices.

The PCB industry is responsible for a significant amount of hazardous waste and energy consumption.

By embracing sustainability in the rigid-flex PCB process, manufacturers can not only comply with regulations but also enhance their brand reputation and potentially reduce operational costs.

Adopting Green Chemistry Practices

Green chemistry focuses on designing chemical processes that reduce or eliminate hazardous substances.

In the rigid-flex PCB manufacturing process, employing green chemistry can significantly lower the environmental impact. Some common green chemistry practices include:

- Non-toxic Materials: Replacing traditional chemicals with eco-friendly alternatives can reduce harmful emissions and waste.

For instance, using water-based inks instead of solvents can minimize volatile organic compounds (VOCs) released into the atmosphere. - Safer Solvents: When solvents are essential in the process, choosing safer options, such as supercritical carbon dioxide or bio-based solvents, can reduce toxicity.

These alternatives break down faster and have less impact on the environment. - Elimination of Heavy Metals: Heavy metals like lead, cadmium, and mercury have been commonly used in electronics manufacturing.

Adopting lead-free solder and other heavy metal-free components aligns with the movement towards reducing hazardous waste in rigid-flex PCB production.

Reduced Waste Techniques

In addition to adopting green chemistry principles, implementing reduced waste techniques plays a critical role in enhancing sustainability.

Here are several strategies that can be employed:

- Streamlined Processes: Optimizing the manufacturing process can lead to less wasted material.

Companies should continuously evaluate and refine their production lines to eliminate inefficiencies and reduce scrap. - Recycling and Reuse: Establishing a recycling program for scrap materials can divert waste from landfills.

Many components used in rigid-flex PCBs can be reclaimed and reused, reducing the need for new materials. - Closed-Loop Systems: Implementing closed-loop systems in the manufacturing process can drastically minimize waste.

These systems allow companies to recycle solvents and chemicals back into the production line, reducing the need for new resources. - On-Demand Production: Moving towards a just-in-time production model reduces excess inventory and waste.

By producing only what is needed, manufacturers can prevent overproduction and manage resources more effectively.

Benefits of Sustainable Practices

Adopting sustainability in the rigid-flex PCB process carries numerous benefits.

Firstly, it aligns with global efforts to combat climate change and reduces the overall environmental footprint of electronics production.

Secondly, consumers are increasingly favoring green companies; demonstrating a commitment to sustainable practices can enhance market competitiveness and customer loyalty.

Moreover, regulatory compliance is a growing concern, and companies that proactively adopt sustainable methods will find it easier to meet stringent policy standards.

Additionally, long-term cost savings can be realized through waste reduction and increased efficiency in manufacturing processes.

Conclusion

Sustainability in the rigid-flex PCB process is not merely a trend; it is a necessary evolution in the electronics industry.

By adopting green chemistry and reducing waste techniques, manufacturers can significantly lessen their environmental impact while still delivering high-quality products.

The journey towards sustainability is ongoing, but the benefits are immense—not only for the planet but also for the businesses that make these crucial changes.

As the industry continues to advance, sustainable practices will be at the forefront, shaping the future of electronics manufacturing.