Flex-Rigid PCBs in Military and Space Applications

Flex-rigid PCBs, or flexible-rigid printed circuit boards, have become an essential component in military and space applications due to their ability to withstand extreme conditions.

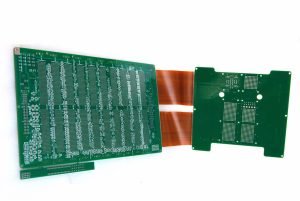

These specialized PCBs are designed to be flexible in certain areas while remaining rigid in others, allowing them to be used in environments where traditional rigid PCBs would fail.

In this article, we will explore the importance of flex-rigid PCBs in military and space applications and how they help ensure the success of missions in these challenging environments.

One of the key advantages of flex-rigid PCBs is their ability to withstand high levels of shock and vibration.

In military applications, such as in fighter jets or tanks, these PCBs are subjected to intense vibrations and sudden impacts.

Traditional rigid PCBs would be prone to cracking or breaking under these conditions, leading to system failures.

Flex-rigid PCBs, on the other hand, are able to flex and bend without compromising their structural integrity, making them ideal for use in these harsh environments.

In space applications, where temperatures can fluctuate drastically and radiation levels are high, flex-rigid PCBs play a crucial role in ensuring the reliability of electronic systems.

Traditional rigid PCBs would struggle to cope with the extreme temperatures and radiation levels found in space, leading to malfunctions or complete system failures.

Flex-rigid PCBs, with their ability to flex and adapt to changing conditions, are able to maintain their functionality even in the harshest of environments.

Another important advantage of flex-rigid PCBs is their compact size and lightweight design.

In military and space applications, where space is limited and weight restrictions are strict, these PCBs offer a significant advantage over traditional rigid PCBs.

By combining the flexibility of a flexible PCB with the rigidity of a rigid PCB, flex-rigid PCBs are able to pack more functionality into a smaller footprint, making them ideal for use in compact electronic systems.

Furthermore, flex-rigid PCBs offer improved signal integrity and reduced electromagnetic interference (EMI) compared to traditional rigid PCBs.

In military applications, where communication is critical for mission success, these PCBs help ensure that signals are transmitted accurately and reliably.

In space applications, where sensitive electronic equipment is exposed to high levels of radiation, the reduced EMI provided by flex-rigid PCBs helps protect electronic components from interference and damage.

Overall, flex-rigid PCBs have revolutionized the way electronic systems are designed and implemented in military and space applications.

Their ability to withstand extreme conditions, compact size, lightweight design, and improved signal integrity make them an essential component in ensuring the success of missions in these challenging environments.

As technology continues to advance and the demands of military and space applications become more complex, flex-rigid PCBs will continue to play a vital role in pushing the boundaries of what is possible in these high-stakes environments.