Support for Advanced Technologies: Rigid flex PCBs can support advanced technologies like 5G, AI, and machine learning, which are increasingly integrated into smart devices

As smart devices continue to evolve, integrating advanced technologies like 5G, artificial intelligence (AI), and machine learning (ML) has become essential to meet the growing demands for speed, efficiency, and intelligence.

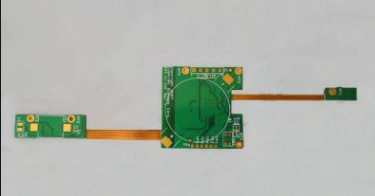

Rigid-flex printed circuit boards (PCBs) have emerged as a critical enabler of these technologies, providing the performance, reliability, and flexibility required to support next-generation applications.

Their unique design and capabilities make rigid-flex PCBs an ideal choice for devices that leverage cutting-edge technologies.

One of the key areas where rigid-flex PCBs excel is in supporting 5G technology.

The rollout of 5G networks has created a demand for devices that can handle higher data speeds, lower latency, and increased connectivity.

Rigid-flex PCBs are well-suited to meet these demands due to their ability to support high-frequency signals and minimize signal loss.

The integration of rigid and flexible sections allows for optimized signal paths, reducing electromagnetic interference (EMI) and ensuring reliable performance in 5G-enabled devices such as smartphones, IoT sensors, and communication infrastructure.

In addition to 5G, rigid-flex PCBs play a vital role in enabling AI and machine learning applications.

AI-powered devices, such as smart assistants, autonomous vehicles, and robotics, require high-performance computing capabilities in compact and efficient designs. Rigid-flex PCBs support these requirements by providing high-density interconnects, efficient thermal management, and the ability to integrate multiple components into a single board. This not only enhances the performance of AI systems but also reduces the size and weight of the devices, making them more practical for real-world applications.

The flexibility of rigid-flex PCBs is particularly advantageous for AI and ML applications that involve complex, multi-functional systems.

For example, in autonomous vehicles, rigid-flex PCBs can connect sensors, processors, and communication modules across different parts of the vehicle, ensuring seamless data flow and real-time decision-making. Similarly, in robotics, rigid-flex PCBs enable the creation of compact and agile designs that can perform intricate tasks with precision.

Another area where rigid-flex PCBs support advanced technologies is in wearable devices and medical equipment. AI-powered wearables, such as fitness trackers and health monitors, rely on rigid-flex PCBs to deliver high performance in a lightweight and flexible form factor.

These devices require efficient power management, reliable connectivity, and the ability to withstand constant movement, all of which are made possible by the robust design of rigid-flex PCBs.

In medical applications, rigid-flex PCBs enable the development of advanced diagnostic tools and implantable devices that leverage AI and ML to improve patient outcomes.

Furthermore, the ability of rigid-flex PCBs to support advanced technologies extends to edge computing and IoT devices.

As more processing is done at the edge of networks, devices need to be capable of handling complex computations while maintaining energy efficiency.

Rigid-flex PCBs provide the necessary performance and flexibility to meet these demands, enabling the development of smarter and more connected IoT ecosystems.

In conclusion, rigid-flex PCBs are at the forefront of enabling advanced technologies like 5G, AI, and machine learning in smart devices.

Their ability to support high-performance computing, efficient thermal management, and compact designs makes them indispensable for next-generation applications. As these technologies continue to transform industries, rigid-flex PCBs will remain a critical component, driving innovation and shaping the future of electronics.