Benefits of Integrating Rigid and Flexible Sections in Assembly Process

In the world of manufacturing, efficiency is key. Companies are constantly looking for ways to streamline their processes and reduce costs while maintaining high quality standards.

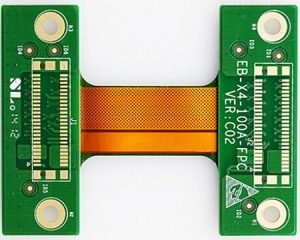

One way to achieve this is by integrating rigid and flexible sections in the assembly process.

By combining these two types of sections, manufacturers can create a more efficient and cost-effective assembly process that reduces labor and time.

Rigid sections are typically used for components that require precise alignment and stability. These sections are often made of materials such as metal or plastic and are designed to provide structural support. On the other hand, flexible sections are used for components that require some degree of flexibility or movement. These sections are often made of materials such as rubber or silicone and are designed to absorb shock or vibration.

By integrating rigid and flexible sections in the assembly process, manufacturers can take advantage of the strengths of each type of section. Rigid sections provide stability and precision, while flexible sections provide flexibility and shock absorption. This combination allows manufacturers to create assemblies that are both sturdy and resilient, reducing the likelihood of defects or failures.

One of the key benefits of integrating rigid and flexible sections in the assembly process is the reduction of labor. By using a combination of rigid and flexible sections, manufacturers can simplify the assembly process and reduce the number of steps required to complete a product. This not only saves time but also reduces the risk of errors or defects that can occur during assembly.

Additionally, integrating rigid and flexible sections can help manufacturers reduce the overall cost of production. By streamlining the assembly process and reducing labor, manufacturers can lower their production costs and increase their profit margins. This cost savings can be passed on to consumers in the form of lower prices, making products more affordable and competitive in the marketplace.

Another benefit of integrating rigid and flexible sections in the assembly process is the improved quality of the final product. By using a combination of rigid and flexible sections, manufacturers can create assemblies that are more durable and reliable. This can lead to fewer returns or warranty claims, saving manufacturers time and money in the long run.

Overall, the integration of rigid and flexible sections in the assembly process offers numerous benefits for manufacturers. By combining the strengths of both types of sections, manufacturers can create assemblies that are more efficient, cost-effective, and high-quality. This can help manufacturers stay competitive in the marketplace and meet the demands of consumers for reliable and affordable products.