Benefits of Rigid Flex PCB Technology

In today’s fast-paced technological landscape, staying ahead of the curve is essential for businesses looking to remain competitive.

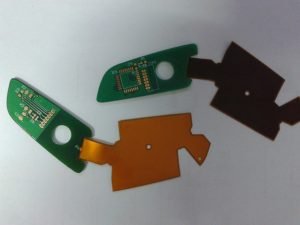

One way to achieve this is by leveraging cutting-edge rigid flex PCB technology. Rigid flex PCBs offer a unique combination of flexibility and durability, making them ideal for a wide range of applications across various industries.

One of the key benefits of rigid flex PCB technology is its ability to reduce the overall size and weight of electronic devices.

By combining rigid and flexible PCBs into a single unit, designers can create more compact and lightweight products without sacrificing performance.

This is particularly important in industries such as aerospace, automotive, and medical devices, where space and weight constraints are critical considerations.

Another advantage of rigid flex PCB technology is its enhanced reliability. Traditional PCBs are prone to failure due to factors such as vibration, shock, and thermal cycling. Rigid flex PCBs, on the other hand, are more resistant to these environmental stresses, resulting in a longer lifespan for electronic devices. This increased reliability can lead to cost savings for businesses by reducing the need for frequent repairs and replacements.

Furthermore, rigid flex PCB technology offers improved signal integrity and EMI/RFI shielding.

The flexible portions of the PCB can be used to route high-speed signals, while the rigid portions provide a stable platform for components.

This design allows for better signal transmission and reduced electromagnetic interference, resulting in higher performance and reliability for electronic devices.

Additionally, rigid flex PCB technology enables designers to create more complex and innovative product designs.

The flexibility of the PCBs allows for unique form factors and 3D configurations that would be impossible with traditional rigid PCBs.

This opens up new possibilities for product differentiation and customization, giving businesses a competitive edge in the market.

Moreover, rigid flex PCB technology can streamline the manufacturing process and reduce assembly costs.By combining multiple PCBs into a single unit, designers can eliminate the need for connectors and cables, simplifying the assembly process and reducing the risk of errors. This can lead to faster time-to-market for products and lower production costs for businesses.

In conclusion, rigid flex PCB technology offers a wide range of benefits for businesses looking to stay ahead of the curve in today’s competitive market.

From reducing size and weight to improving reliability and signal integrity, rigid flex PCBs provide a versatile solution for a variety of applications.

By leveraging this cutting-edge technology, businesses can create innovative products that meet the demands of today’s consumers and gain a competitive advantage in their respective industries.