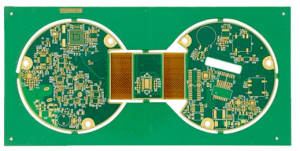

Benefits of SMT Assembly Integration in Rigid-Flexible PCB Manufacturing

In the world of electronics manufacturing, the demand for smaller, lighter, and more flexible devices is constantly increasing. This has led to the rise of rigid-flex PCBs, which offer a combination of rigid and flexible substrates in a single board.One of the key processes in manufacturing rigid-flex PCBs is surface mount technology (SMT) assembly. Integrating SMT assembly into the production of rigid-flex PCBs offers a range of benefits that can help manufacturers meet the demands of today’s market.

One of the primary benefits of integrating SMT assembly into rigid-flex PCB manufacturing is increased efficiency. SMT assembly is a highly automated process that allows for the rapid placement of components onto the PCB. This can significantly reduce production time and costs, as well as improve overall product quality. By streamlining the assembly process, manufacturers can increase their output and meet tight deadlines more easily.

Another benefit of SMT assembly integration is improved reliability. SMT components are smaller and lighter than through-hole components, which can lead to better signal integrity and reduced electromagnetic interference. This is especially important in rigid-flex PCBs, where space is limited and components must be placed close together. By using SMT assembly, manufacturers can ensure that their products are more reliable and durable, leading to higher customer satisfaction and fewer returns.

Additionally, integrating SMT assembly into rigid-flex PCB manufacturing allows for greater design flexibility. SMT components can be placed on both the rigid and flexible portions of the board, allowing for more complex and compact designs. This can be particularly useful in applications where space is at a premium, such as wearable devices or medical implants. By using SMT assembly, manufacturers can create innovative and cutting-edge products that meet the needs of today’s consumers.

Furthermore, SMT assembly integration can lead to cost savings for manufacturers. SMT components are typically less expensive than through-hole components, which can help reduce overall production costs. Additionally, the automated nature of SMT assembly means that fewer labor hours are required, further lowering expenses. By optimizing their manufacturing processes with SMT assembly, manufacturers can improve their bottom line and remain competitive in the market.

In conclusion, integrating SMT assembly into rigid-flex PCB manufacturing offers a range of benefits that can help manufacturers meet the demands of today’s market. From increased efficiency and reliability to greater design flexibility and cost savings, SMT assembly can help manufacturers create high-quality products that meet the needs of consumers. By embracing this technology, manufacturers can stay ahead of the curve and continue to innovate in the world of electronics manufacturing.