Signal Integrity and Thermal Management in Rigid-Flex PCB Design

Signal integrity and thermal management are critical considerations in the design and manufacturing of rigid-flex printed circuit boards (PCBs).

As technology continues to advance, the demand for compact and efficient electronic devices increases, making the intricacies of PCB design more complex.

Rigid-flex PCBs combine the best features of both rigid and flexible circuits, but their unique characteristics require careful planning to ensure optimal performance.

Understanding Rigid-Flex PCB Design

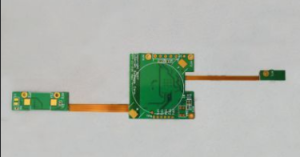

Rigid-flex PCBs are hybrid circuits that incorporate both rigid and flexible substrates.

This design allows for versatile configurations, making them highly suitable for applications in aerospace, medical devices, and consumer electronics.

However, integrating these two types of substrates presents unique challenges, particularly concerning signal integrity and thermal management.

The Importance of Signal Integrity

Signal integrity refers to the quality of an electrical signal as it travels through a circuit.

Factors that can compromise signal integrity include noise, crosstalk, impedance mismatches, and reflections.

In rigid-flex designs, preserving signal integrity is vital due to the compact nature of these boards and the complex routing paths often involved.

Key Factors Influencing Signal Integrity

- Material Selection: The choice of dielectric materials plays a crucial role.

Materials with favorable dielectric constants and low loss tangents can significantly improve signal quality. - Impedance Control: Ensuring uniform impedance throughout the PCB is essential.

Techniques such as controlled trace width and the use of ground planes help maintain consistent impedance levels. - Trace Design: The geometry of traces can affect the electromagnetic fields surrounding them.

It is essential to consider trace width, spacing, and length to minimize undesired effects like crosstalk. - Grounding and Shielding: Proper grounding techniques can help mitigate interference.

Additionally, incorporating shielding can protect sensitive signal paths from external noise. - Simulation and Analysis: Utilizing simulation tools during the design phase allows engineers to predict and address potential issues related to signal integrity before physical prototypes are produced.

Managing Thermal Challenges

Thermal management is another essential aspect of rigid-flex PCB design. Excess heat can degrade performance, cause components to fail, and shorten the lifespan of the PCB.

Effective thermal management strategies are crucial to ensure the reliability and robustness of rigid-flex designs.

Effective Thermal Management Techniques

- Thermal Modeling: Before fabrication, thermal modeling can help visualize heat distribution across the PCB.

This process identifies hotspots and allows for necessary adjustments, such as altering component placement or trace design. - Thermal Via Usage: Thermal vias can be incorporated into the design to dissipate heat more effectively.

These small plated holes connect one layer of the PCB to another, allowing heat to move vertically through the board. - Heat Sinks and Spreading: Integrating heat sinks or utilizing thermal spreaders can help manage excessive heat.

These components are designed to absorb and dissipate heat away from critical areas. - Component Selection: Choosing components that produce less heat or have higher thermal tolerances can make a significant difference in managing overall thermal performance.

- Airflow Considerations: For applications where airflow is possible, designing the enclosure to promote airflow around the PCB can aid in cooling.

This approach is particularly beneficial in larger systems or where active cooling solutions are feasible.

The Balance Between Signal Integrity and Thermal Management

Designing rigid-flex PCBs requires a careful balance between signal integrity and thermal management.

Compromising one for the other can lead to diminished performance and reliability.

Collaboration among electrical engineers, thermal analysts, and mechanical designers is vital to ensure that both aspects are addressed harmoniously.

Conclusion

Signal integrity and thermal management are paramount in rigid-flex PCB design.

As devices continue to shrink in size while increasing in functionality, it becomes even more critical to adopt multi-faceted approaches that address both electrical and thermal challenges.

By leveraging advanced materials, simulating designs, and implementing effective design strategies, engineers can create more robust and reliable rigid-flex PCBs that meet the demands of modern technology.

The intricacies of these designs may be complex, but the potential for innovative solutions is immense, driving the future of electronics forward.