Signal Integrity and Thermal Management in Rigid-Flex PCB Design

Signal integrity and thermal management are critical factors that engineers must consider during the design of rigid-flex printed circuit boards (PCBs).

As technology advances, the demands placed on PCBs are increasing, especially in industries like telecommunications, consumer electronics, and aerospace.

Understanding how to maintain signal integrity while effectively managing heat can lead to more reliable and efficient product performance.

Understanding Rigid-Flex PCBs

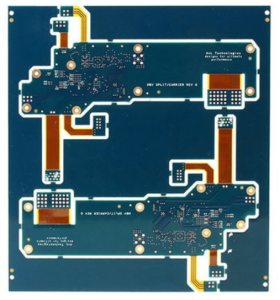

Rigid-flex PCBs combine the best of both worlds—rigid and flexible circuits.

They allow for intricate designs and versatile applications while reducing the size and weight of the end product.

This type of PCB is made by bonding flexible and rigid materials together, providing a unique solution for applications where space is constrained.

However, designing these PCBs comes with its own set of challenges, particularly in maintaining signal integrity across various components and managing heat generated during operation.

Importance of Signal Integrity

Signal integrity refers to the quality of the electrical signals transmitted through the circuit.

Poor signal integrity can lead to errors, data loss, and reduced performance.

In rigid-flex PCB design, achieving signal integrity involves considering various factors, including impedance control, crosstalk, and electromagnetic interference (EMI).

Impedance Control

One of the most significant aspects of achieving good signal integrity is maintaining controlled impedance throughout the circuit.

Each trace on a PCB has its own characteristic impedance determined by its width, thickness, and the dielectric material used.

The design must ensure that the impedance of each trace matches the components connected to it. This helps prevent signal reflections, a common issue that can degrade performance.

Crosstalk and EMI

Crosstalk occurs when signals in adjacent traces interfere with one another, leading to signal distortion.

In rigid-flex designs, where traces may be routed closely together to save space, this is a significant concern.

Designers must implement strategies such as trace spacing, differential signaling, and ground planes to mitigate crosstalk.

Similarly, EMI can cause interference in signal integrity, which can be managed by proper shielding, grounding, and trace routing techniques.

Thermal Management Challenges

Thermal management is equally important in the design of rigid-flex PCBs.

As circuits operate, they generate heat, which can affect performance and reliability.

Excessive heat can lead to thermal runaway, component failure, or reduced lifespan of the PCB.

Therefore, effective thermal management solutions must be integrated into the design from the outset.

Heat Dissipation Methods

There are various strategies to dissipate heat effectively from rigid-flex PCBs.

One common method is the use of thermal vias, which allow heat to transfer from the surface layers of the PCB to inner layers, where it may be more efficiently dissipated.

Additionally, materials with good thermal conductivity can be used to assist in heat distribution across the board.

Another effective technique is the implementation of heat sinks. These components help absorb and dissipate heat away from critical areas of the PCB.

Using thermal pads to improve contact between heat-generating components and heat sinks can also enhance thermal management.

Material Selection

The materials chosen for a rigid-flex PCB can significantly influence both signal integrity and thermal management.

For instance, dielectric materials with low loss characteristics can help maintain signal integrity by minimizing signal degradation.

At the same time, selecting materials with high thermal conductivity can aid in effective heat dissipation.

By carefully evaluating the materials used in the PCB design, engineers can enhance both performance and reliability.

The Role of Simulation in Design

Simulation tools have become invaluable in optimizing signal integrity and thermal management during the design phase.

Engineers can use these tools to model and analyze how signals will behave in the PCB and how heat will disperse across the board.

This proactive approach allows for adjustments before production, saving time and resources in the long run.

Using simulations for various scenarios, such as temperature fluctuations and signal interference patterns, enables designers to create robust solutions that are tailored to the specific needs of the application.

Conclusion

In summary, signal integrity and thermal management are paramount in the design of rigid-flex PCBs.

By understanding and addressing the unique challenges posed by these boards, engineers can create efficient, reliable, and high-performance products.

A strategic approach involving controlled impedance, effective heat dissipation methods, thoughtful material selection, and advanced simulation can significantly elevate the quality of rigid-flex PCB designs.

As technology continues to evolve, mastering these principles will be essential for engineers seeking to push the boundaries of innovation in electronics.