Robust Rigid-Flex Designs for Automotive IoT Sensors in Harsh Environments

Robust rigid-flex designs are essential for automotive IoT sensors operating in harsh environments.

With modern vehicles increasingly relying on sophisticated sensors for enhanced safety and performance, the demand for reliable and durable designs is at an all-time high.

This article delves into the critical role of rigid-flex technology in automotive IoT applications, the challenges faced in harsh environments, and the benefits of using these advanced designs.

Understanding Rigid-Flex Technology

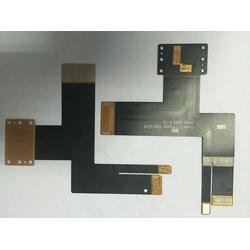

Rigid-flex technology combines the best features of both rigid and flexible printed circuit boards (PCBs).

Rigid PCBs provide a sturdy foundation capable of housing complex electronic components, while flexible PCBs offer the adaptability and space efficiency needed in confined areas.

This fusion allows for the creation of compact, lightweight designs suitable for a variety of automotive applications.

In the context of IoT sensors, the integration of rigid-flex designs helps in meeting specific requirements such as size constraints and environmental resilience.

Automotive sensors are increasingly being installed in areas that experience extreme temperatures, vibrations, and exposure to chemicals.

Therefore, utilizing robust rigid-flex designs ensures the longevity and performance of these sensors.

Challenges in Harsh Environments

Automotive environments present a multitude of challenges that can compromise the functionality of IoT sensors.

For instance, temperature fluctuations can affect the electronic components, leading to potential failure. Moreover, exposure to moisture, dust, and road debris increases the risk of damage.

Some common challenges faced include:

- Temperature Extremes: Automotive sensors may experience temperatures ranging from cold winter conditions to extremely high summer heat.

These fluctuations can lead to thermal expansion and contraction, which puts stress on electronic components. - Vibration and Shock: Vehicles are subject to constant vibrations and shocks from uneven roads.

Components within the sensors must be able to withstand these forces without compromising their mechanical integrity. - Chemical Exposure: Automotive environments often expose sensors to oils, fuels, and cleaning agents.

These chemicals can degrade materials used in circuit design, underscoring the need for robust protective measures.

Advantages of Rigid-Flex Designs

Enhanced Durability

The most significant advantage of rigid-flex designs is their enhanced durability.

By incorporating flexible features, these designs can absorb shocks and vibrations that would typically damage traditional rigid PCBs.

Furthermore, the bonding of rigid and flexible materials creates a more resilient structure capable of enduring harsh conditions.

Space Efficiency

Space is a premium in automotive applications.

Rigid-flex designs are often compact, enabling manufacturers to save valuable space while fitting essential components into smaller areas.

This advantage is critical for modern vehicles that house numerous sensors without compromising design aesthetics or performance.

Simplified Assembly and Reduced Weight

Rigidity in certain sections and flexibility in others simplifies assembly by minimizing the need for connectors.

Fewer components mean less potential for failure and easier installation.

Moreover, the lightweight nature of rigid-flex designs contributes to the overall efficiency of the vehicle, aiding in fuel economy and performance.

Improved Signal Integrity

Signal integrity is vital for IoT sensors that relay real-time data.

Rigid-flex designs can provide an optimized path for signals, reducing interference and ensuring that data transmission is both reliable and efficient.

High-quality electrical connections improve the overall performance of automotive IoT systems.

Key Considerations for Implementation

Implementing robust rigid-flex designs in automotive IoT sensors involves several critical considerations:

- Material Selection: The materials chosen for rigid-flex PCBs must be capable of withstanding temperature variations, humidity, and chemical exposure.

High-grade polyimide and epoxy resin materials are often preferred. - Testing Protocols: Thorough testing procedures must be in place to simulate the environmental stresses that sensors may encounter.

This can include thermal cycling tests, vibration tests, and exposure to chemicals. - Design Optimization: The layout of the PCB should be optimized to minimize potential mechanical stresses while ensuring electronic performance.

This requires a deep understanding of both material properties and electronic design principles.

Conclusion

In conclusion, robust rigid-flex designs for automotive IoT sensors are indispensable in ensuring the reliability and functionality of modern vehicles in harsh environments.

By addressing the challenges posed by temperature extremes, vibration, and chemical exposure, these designs enhance durability while optimizing space and weight.

As the automotive industry continues to develop smarter and more efficient vehicles, embracing advanced rigid-flex technologies will be crucial for the success of automotive IoT applications.

Ultimately, the integration of such designs not only improves vehicle performance but also contributes to heightened safety and user experience on the road.