Rigid-Flexible PCBs: Strategies for Successful SMT Assembly

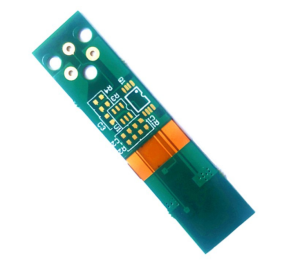

Rigid-flex PCBs have become increasingly popular in the electronics industry due to their ability to combine the benefits of both rigid and flexible PCBs in a single design. These boards offer greater design flexibility, reduced weight, and improved reliability compared to traditional rigid PCBs. However, assembling rigid-flex PCBs can be more challenging than assembling rigid PCBs due to the different materials and construction techniques involved.

One of the key challenges in assembling rigid-flex PCBs is ensuring successful surface mount technology (SMT) assembly. SMT assembly is a critical step in the manufacturing process of rigid-flex PCBs, as it involves mounting electronic components onto the board’s surface. To ensure successful SMT assembly of rigid-flex PCBs, several strategies can be employed.

First and foremost, it is essential to carefully design the rigid-flex PCB layout to optimize the SMT assembly process. The layout should take into account the unique characteristics of rigid-flex PCBs, such as the presence of both rigid and flexible sections. Components should be placed strategically to minimize stress on the flexible sections during assembly and operation. Additionally, the layout should consider the thermal properties of the board to ensure proper heat dissipation during soldering.

Another important strategy for successful SMT assembly of rigid-flex PCBs is to select the right materials and components. The materials used in rigid-flex PCBs should be compatible with the SMT assembly process and capable of withstanding the temperatures and stresses involved. Components should be chosen based on their compatibility with the board’s materials and construction, as well as their ability to withstand the rigors of the assembly process.

Furthermore, it is crucial to work closely with your PCB manufacturer and assembly partner to ensure that the design and materials chosen are suitable for SMT assembly. Collaboration with experienced professionals can help identify potential issues early in the design process and develop solutions to address them. Additionally, your manufacturer can provide valuable insights into best practices for SMT assembly of rigid-flex PCBs based on their expertise and experience.

During the SMT assembly process, it is important to pay close attention to quality control measures to ensure the reliability and performance of the finished product. Inspecting components before assembly, monitoring the soldering process, and conducting thorough testing after assembly are all critical steps in ensuring the quality of the final product. Additionally, it is essential to document the assembly process and any issues encountered to facilitate troubleshooting and continuous improvement.

In conclusion, successful SMT assembly of rigid-flex PCBs requires careful design, selection of materials and components, collaboration with experienced partners, and rigorous quality control measures. By following these strategies and best practices, manufacturers can overcome the challenges associated with assembling rigid-flex PCBs and produce high-quality, reliable products. As the demand for rigid-flex PCBs continues to grow, mastering the art of SMT assembly will be essential for staying competitive in the electronics industry.