Benefits of Using Rigid-Flexible PCBs in Electronic Devices

Rigid-flex PCBs, or rigid-flexible printed circuit boards, have become increasingly popular in the electronics industry due to their numerous benefits and advantages. These innovative PCBs combine the best of both rigid and flexible circuit boards, offering a unique solution for electronic devices that require both stability and flexibility. In this article, we will explore the materials and manufacturing processes involved in creating rigid-flex PCBs, as well as the benefits of using them in electronic devices.

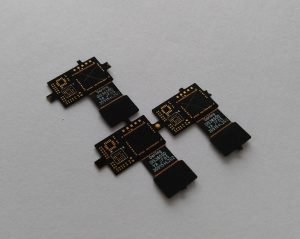

Rigid-flex PCBs are made up of a combination of rigid and flexible materials, typically consisting of multiple layers of rigid FR4 material connected by flexible polyimide layers. The rigid sections provide stability and support for components, while the flexible sections allow the PCB to bend and conform to the shape of the device. This combination of materials allows for greater design flexibility and reliability in electronic devices.

The manufacturing process for rigid-flex PCBs is more complex than traditional rigid or flexible PCBs, requiring specialized equipment and expertise.

The process typically involves laminating together layers of rigid and flexible materials, drilling holes for component placement, and etching copper traces to create the circuit connections. This intricate process requires precision and attention to detail to ensure the final product meets the required specifications.

One of the key benefits of using rigid-flex PCBs in electronic devices is their ability to reduce the overall size and weight of the device.

By combining the functionality of both rigid and flexible PCBs into a single board, designers can create more compact and lightweight devices without sacrificing performance or reliability. This is especially important in portable electronic devices where space and weight are critical factors.

Another benefit of rigid-flex PCBs is their improved reliability and durability compared to traditional PCBs. The flexible sections of the PCB help to absorb mechanical stress and vibrations, reducing the risk of component failure due to bending or flexing. This increased durability makes rigid-flex PCBs ideal for applications where the device may be subjected to harsh environments or frequent movement.

In addition to their size, weight, and reliability benefits, rigid-flex PCBs also offer improved signal integrity and electromagnetic interference (EMI) performance. The combination of rigid and flexible materials helps to reduce signal loss and crosstalk, resulting in better overall performance and reliability for the electronic device. This is especially important in high-speed and high-frequency applications where signal integrity is critical.

Overall, the use of rigid-flex PCBs in electronic devices offers a wide range of benefits, including reduced size and weight, improved reliability and durability, and enhanced signal integrity and EMI performance. While the manufacturing process for rigid-flex PCBs may be more complex and costly than traditional PCBs, the advantages they offer make them a valuable investment for electronic device manufacturers. As technology continues to evolve, rigid-flex PCBs will likely become even more prevalent in a wide range of electronic devices, from smartphones and tablets to medical devices and automotive systems.