Benefits of Using Rigid-Flexible PCBs in Electronic Devices

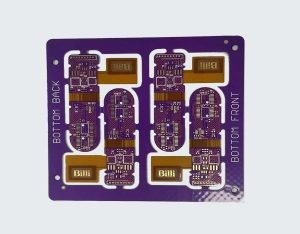

Rigid-flex PCBs, or rigid-flexible printed circuit boards, have become increasingly popular in the electronics industry due to their numerous benefits and advantages. These innovative PCBs combine the best of both rigid and flexible circuit boards, offering a unique solution for electronic devices that require both structural stability and flexibility. In this article, we will explore the manufacturing process of rigid-flex PCBs and how they are assembled using surface mount technology (SMT).

The manufacturing process of rigid-flex PCBs involves combining rigid and flexible substrates into a single board. This process requires specialized equipment and expertise to ensure that the different materials are properly bonded together. The rigid portions of the PCB provide structural support and stability, while the flexible portions allow for bending and folding to fit into tight spaces or odd-shaped enclosures.

One of the key benefits of using rigid-flex PCBs in electronic devices is their ability to reduce the overall size and weight of the device.

By eliminating the need for bulky connectors and cables, rigid-flex PCBs can help designers create more compact and lightweight products.

This is especially important in industries such as aerospace, medical devices, and wearable technology, where space and weight constraints are critical factors.

Another advantage of rigid-flex PCBs is their improved reliability and durability. Traditional rigid PCBs are prone to mechanical stress and vibration,

which can lead to solder joint failures and other reliability issues. Rigid-flex PCBs, on the other hand, are designed to withstand bending and flexing without compromising the integrity of the circuitry. This makes them ideal for applications that require frequent movement or handling.

In addition to their size and reliability benefits, rigid-flex PCBs also offer cost savings in terms of assembly and maintenance. By eliminating the need for additional connectors and cables, manufacturers can reduce the number of components and solder joints, leading to lower assembly costs and improved overall product quality. Furthermore, the reduced number of interconnects also means fewer points of failure, resulting in lower maintenance and repair costs over the lifetime of the device.

When it comes to assembling rigid-flex PCBs, surface mount technology (SMT) is the preferred method due to its precision and efficiency.

SMT involves placing electronic components directly onto the surface of the PCB, rather than through-holes, which allows for higher component density and faster assembly times. This is especially important for rigid-flex PCBs, where space is limited and components need to be placed in close proximity to each other.

During the SMT assembly process, solder paste is applied to the pads on the PCB, and components are placed onto the paste using a pick-and-place machine. The PCB is then heated in a reflow oven, causing the solder paste to melt and create a strong bond between the components and the board. Once the solder has solidified, the PCB undergoes inspection and testing to ensure that all components are properly soldered and functioning correctly.

In conclusion, rigid-flex PCBs offer a wide range of benefits for electronic devices, including reduced size and weight, improved reliability and durability, and cost savings in assembly and maintenance. By combining the best features of rigid and flexible circuit boards, manufacturers can create innovative products that meet the demands of today’s fast-paced and ever-changing market. With the use of surface mount technology for assembly, rigid-flex PCBs can be manufactured efficiently and with high precision, ensuring that electronic devices are built to the highest standards of quality and performance.