Benefits of Using Rigid-Flexible PCBs in SMT Assembly

Printed circuit boards (PCBs) are an essential component in the electronics industry, serving as the foundation for the assembly of electronic components.

In recent years, there has been a growing demand for more compact and lightweight electronic devices, leading to the development of rigid-flex PCBs.

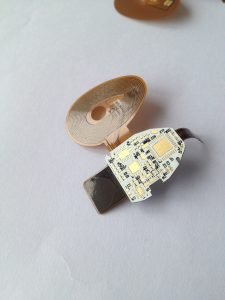

These innovative PCBs combine the benefits of rigid and flexible PCBs, offering a solution that is both durable and versatile.

One of the key benefits of using rigid-flex PCBs in surface mount technology (SMT) assembly is the ability to reduce the overall size and weight of electronic devices. By eliminating the need for bulky connectors and cables, rigid-flex PCBs allow for a more compact and streamlined design. This is particularly advantageous in applications where space is limited, such as in wearable devices and medical implants.

In addition to their space-saving capabilities, rigid-flex PCBs also offer improved reliability and durability compared to traditional rigid PCBs.

The flexible sections of the PCB provide a degree of flexibility that helps to absorb mechanical stress and reduce the risk of damage from bending or twisting. This makes rigid-flex PCBs ideal for applications that require frequent movement or exposure to harsh environmental conditions.

Furthermore, rigid-flex PCBs can help to simplify the assembly process and reduce the number of interconnects required.By integrating multiple PCBs into a single rigid-flex design, manufacturers can eliminate the need for complex wiring harnesses and connectors, reducing the risk of signal interference and improving overall system performance. This streamlined approach to assembly also helps to reduce the overall cost of production, making rigid-flex PCBs a cost-effective solution for high-volume manufacturing.

Another advantage of using rigid-flex PCBs in SMT assembly is the ability to achieve higher levels of precision and accuracy. The flexible nature of the PCB allows for tighter tolerances and more intricate designs, enabling manufacturers to create complex layouts with multiple layers and components.

This level of precision is essential for applications that require high-speed data transmission or precise control of electronic signals.

Overall, the benefits of using rigid-flex PCBs in SMT assembly are clear. From reducing the size and weight of electronic devices to improving reliability and durability, rigid-flex PCBs offer a versatile solution that meets the demands of modern electronics manufacturing. By leveraging the unique properties of rigid-flex PCBs, manufacturers can achieve higher levels of quality and precision in their products, ultimately leading to improved performance and customer satisfaction.