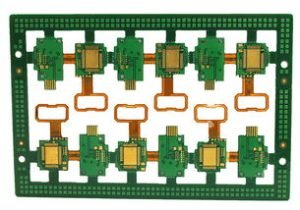

Streamlining SMT Assembly Processes for Rigid-Flexible PCB Manufacturing

Rigid-flex PCBs have become increasingly popular in the electronics industry due to their ability to combine the benefits of both rigid and flexible PCBs.

These boards are ideal for applications where space is limited, and where the board needs to be bent or folded to fit into a specific form factor.

However, manufacturing rigid-flex PCBs can be a complex process, especially when it comes to surface mount technology (SMT) assembly.

One of the key challenges in SMT assembly for rigid-flex PCBs is ensuring that components are properly mounted on both the rigid and flexible portions of the board. This requires careful planning and coordination between the design and assembly teams to ensure that components are placed in the correct locations and orientations. Additionally, the flexibility of the board can make it more difficult to ensure that components are securely attached, as the board may bend or flex during the assembly process.

To optimize SMT assembly procedures for rigid-flex PCB manufacturing, it is important to carefully consider the design of the board and the placement of components. Designing the board with clear boundaries between the rigid and flexible portions can help to ensure that components are mounted in the correct locations. Additionally, using stiffeners or support structures can help to prevent the board from bending or flexing during assembly, making it easier to mount components securely.

Another key consideration in optimizing SMT assembly procedures for rigid-flex PCB manufacturing is the selection of components and materials.

Choosing components that are suitable for use on flexible substrates can help to ensure that they will perform reliably over the lifetime of the board. Additionally, selecting materials that are compatible with the bending and flexing of the board can help to prevent damage to components during assembly.

In addition to careful design and component selection, it is also important to consider the assembly process itself when optimizing SMT assembly procedures for rigid-flex PCB manufacturing. This includes ensuring that the correct soldering techniques are used to attach components to the board, as well as implementing quality control measures to verify that components are mounted correctly.

One way to streamline the SMT assembly process for rigid-flex PCB manufacturing is to use automated assembly equipment.

Automated equipment can help to ensure that components are mounted accurately and securely, reducing the risk of errors or defects during assembly. Additionally, automated equipment can help to increase the speed and efficiency of the assembly process, allowing for higher throughput and lower production costs.

Overall, optimizing SMT assembly procedures for rigid-flex PCB manufacturing requires careful planning and coordination between the design and assembly teams, as well as the selection of appropriate components and materials. By carefully considering these factors and implementing best practices for SMT assembly, manufacturers can ensure that their rigid-flex PCBs are assembled efficiently and reliably, resulting in high-quality products that meet the needs of their customers.