Benefits of Using Rigid-Flexible PCBs in Electronic Devices

Rigid-flex PCBs have become increasingly popular in the electronics industry due to their numerous benefits and advantages over traditional rigid PCBs.

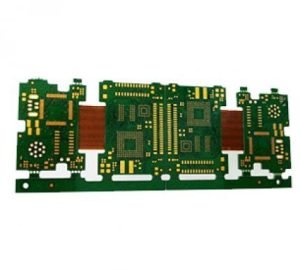

These innovative circuit boards combine the best of both worlds by incorporating rigid and flexible sections into a single board, allowing for greater design flexibility and improved reliability. In this article, we will explore the benefits of using rigid-flex PCBs in electronic devices and how they can enhance the overall performance and functionality of electronic products.

One of the key advantages of using rigid-flex PCBs is their ability to reduce the overall size and weight of electronic devices. By eliminating the need for bulky connectors and cables, rigid-flex PCBs can help manufacturers create more compact and lightweight products without sacrificing performance or functionality. This is especially important in industries where space is limited, such as the medical and aerospace sectors, where every millimeter counts.

In addition to their space-saving benefits, rigid-flex PCBs also offer improved reliability and durability compared to traditional rigid PCBs.

The flexible sections of the board are designed to withstand bending and flexing without compromising the integrity of the circuit, making them ideal for applications that require frequent movement or vibration. This increased durability can help extend the lifespan of electronic devices and reduce the need for costly repairs or replacements.

Another advantage of using rigid-flex PCBs is their ability to simplify the assembly process and reduce manufacturing costs.

By combining multiple PCBs into a single board, manufacturers can streamline the production process and eliminate the need for complex interconnects and connectors. This not only reduces the number of components required for assembly but also minimizes the risk of errors and defects during manufacturing, resulting in higher-quality products and faster time-to-market.

Furthermore, rigid-flex PCBs offer greater design flexibility and customization options compared to traditional rigid PCBs.

Manufacturers can create complex and intricate designs that would be impossible with rigid boards alone, allowing for more innovative and creative product designs. This flexibility also enables manufacturers to optimize the layout of components and circuits for improved performance and efficiency, resulting in higher-quality products that meet the specific needs and requirements of customers.

Overall, the benefits of using rigid-flex PCBs in electronic devices are clear. From space-saving advantages to improved reliability and durability, these innovative circuit boards offer a comprehensive approach to PCB manufacturing and SMT assembly that can enhance the overall performance and functionality of electronic products. As technology continues to evolve and demand for smaller, lighter, and more reliable electronic devices grows, rigid-flex PCBs will undoubtedly play a crucial role in shaping the future of the electronics industry.