Rigid-Flex PCBs: The Backbone of Industrial AIoT Solutions

Rigid-Flex PCBs: The Backbone of Industrial AIoT Solutions

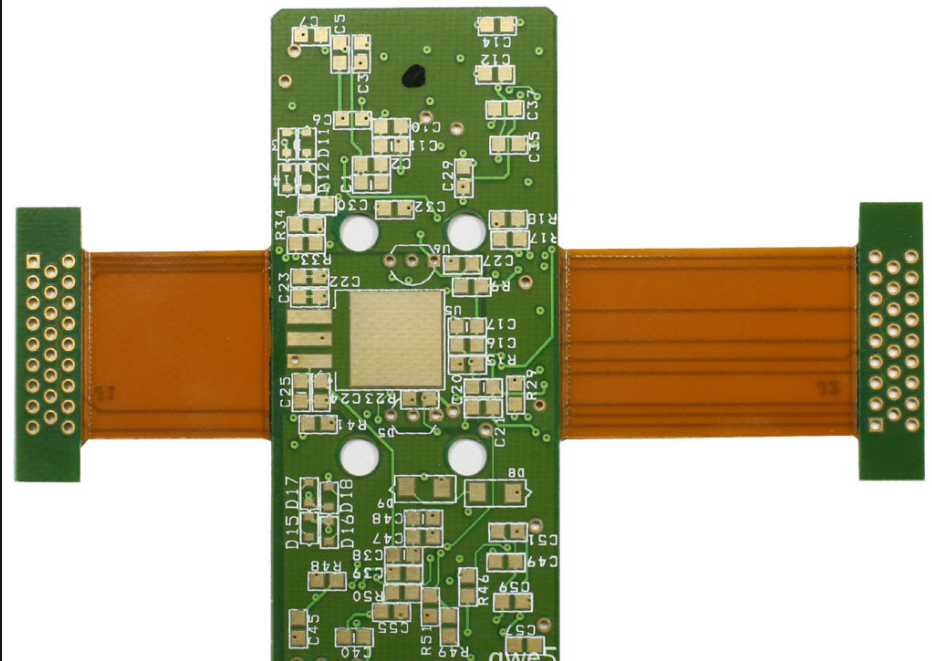

The Industrial Internet of Things (IIoT), often referred to as Industrial AIoT when integrated with artificial intelligence, is transforming the manufacturing and industrial sectors by enabling smarter, more efficient operations. At the core of this transformation are rigid-flex printed circuit boards (PCBs), which provide the reliability, durability, and performance needed to support the complex systems that drive industrial AIoT solutions. These hybrid circuits, which combine the structural stability of rigid boards with the flexibility of flexible circuits, are becoming the backbone of modern industrial automation and smart factory systems.

Enabling Real-Time Data Collection and Analysis

One of the key functions of industrial AIoT is the collection and analysis of real-time data to optimize operations. Rigid-flex PCBs are essential for enabling this capability, as they provide a reliable platform for integrating sensors, processors, and communication modules. For example, in predictive maintenance systems, rigid-flex PCBs connect sensors that monitor equipment health, such as vibration, temperature, and pressure. These sensors collect data in real time, which is then analyzed to predict potential failures and schedule maintenance before issues arise. The durability of rigid-flex PCBs ensures that these systems can operate reliably in harsh industrial environments, such as high temperatures, vibrations, and exposure to chemicals.

Supporting Smart Factory Automation

Smart factories rely on interconnected systems to automate production processes and improve efficiency. Rigid-flex PCBs play a critical role in enabling this automation by providing the connectivity and performance needed for advanced robotics and control systems. For instance, in robotic arms, rigid-flex PCBs integrate sensors, motors, and control units, enabling precise and efficient operation. The flexibility of these circuits allows for compact and ergonomic designs, which are essential for integrating robotics into existing production lines. Additionally, the durability of rigid-flex PCBs ensures that these systems can withstand the rigors of continuous operation, reducing downtime and maintenance costs.

Enhancing Industrial Communication Networks

Industrial AIoT solutions require robust communication networks to enable seamless data exchange between devices and systems. Rigid-flex PCBs are used to connect communication modules, such as Wi-Fi, Bluetooth, and 5G, ensuring reliable and high-speed data transmission. For example, in a smart factory, rigid-flex PCBs enable the integration of wireless communication modules into machines and equipment, allowing them to communicate with each other and with central control systems. This connectivity enables real-time monitoring and control of production processes, improving efficiency and reducing errors.

Driving Innovation in Industrial Wearables

Wearable devices are becoming increasingly important in industrial settings, where they are used to monitor workers’ health and safety. Rigid-flex PCBs are essential for enabling the development of these devices, as they provide the flexibility and durability needed for wearable applications. For example, in safety helmets, rigid-flex PCBs integrate sensors that monitor environmental conditions, such as gas levels and temperature, as well as biometric sensors that track workers’ health. These devices can alert workers to potential hazards and provide real-time data to safety managers, improving workplace safety and reducing the risk of accidents.

Enabling Edge Computing in Industrial AIoT

Edge computing is a critical component of industrial AIoT, enabling real-time data processing and decision-making at the edge of the network. Rigid-flex PCBs are essential for implementing edge computing in industrial devices, as they provide the performance and reliability needed for high-speed data processing. For example, in industrial cameras, rigid-flex PCBs integrate processors and memory modules, enabling real-time image analysis for quality control and defect detection. The compact design of rigid-flex PCBs allows for the integration of these components into small and portable devices, making them ideal for edge computing applications.

Supporting Sustainable Manufacturing Practices

Sustainability is becoming a key focus in the industrial sector, and rigid-flex PCBs are playing a role in enabling more sustainable manufacturing practices. For example, in energy management systems, rigid-flex PCBs connect sensors and control units that monitor and optimize energy usage, reducing waste and improving efficiency. Additionally, the use of eco-friendly materials and manufacturing processes in the production of rigid-flex PCBs aligns with the growing emphasis on sustainability in the electronics industry.

Conclusion

Rigid-flex PCBs are the backbone of industrial AIoT solutions, providing the reliability, durability, and performance needed to support the complex systems that drive modern industrial automation. By enabling real-time data collection and analysis, supporting smart factory automation, enhancing communication networks, driving innovation in industrial wearables, enabling edge computing, and supporting sustainable manufacturing practices, rigid-flex PCBs are playing a transformative role in the industrial sector. As industrial AIoT continues to evolve, the demand for rigid-flex PCBs will only grow, ensuring that industrial operations remain efficient, connected, and sustainable.