Rigid-Flex PCBs in Healthcare: Transforming AIoT Medical Devices

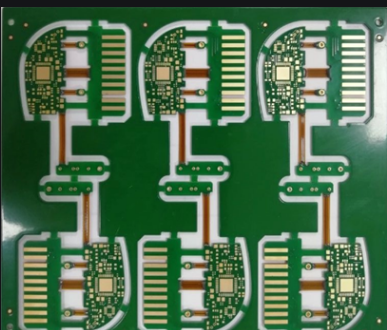

The healthcare industry is undergoing a digital transformation, driven by the integration of Artificial Intelligence of Things (AIoT) technologies. At the heart of this transformation are rigid-flex printed circuit boards (PCBs), which are enabling the development of advanced medical devices that improve patient care, enhance diagnostic accuracy, and streamline healthcare operations. By combining the durability of rigid boards with the flexibility of flexible circuits, rigid-flex PCBs are revolutionizing the design and functionality of AIoT medical devices.

1. Enabling Compact and Wearable Medical Devices

Wearable medical devices, such as fitness trackers, glucose monitors, and ECG patches, are becoming increasingly popular for continuous health monitoring. Rigid-flex PCBs are ideal for these applications due to their compact and lightweight design.

Applications:

- Smartwatches: Rigid-flex PCBs enable the integration of sensors, processors, and communication modules into sleek and ergonomic designs, allowing users to monitor their health in real time.

- Implantable Devices: In devices like pacemakers and neurostimulators, rigid-flex PCBs provide the durability and biocompatibility needed for long-term implantation.

2. Enhancing Diagnostic Accuracy

AIoT medical devices rely on accurate data collection and analysis to provide reliable diagnostics. Rigid-flex PCBs enable the integration of high-precision sensors and advanced processing capabilities, ensuring accurate and timely diagnostics.

Applications:

- Medical Imaging: In devices like ultrasound machines and MRI scanners, rigid-flex PCBs support high-resolution imaging and real-time data processing, improving diagnostic accuracy.

- Point-of-Care Testing: Rigid-flex PCBs enable the development of portable diagnostic devices that can perform complex tests at the patient’s bedside, reducing the need for laboratory analysis.

3. Supporting Remote Patient Monitoring

Remote patient monitoring is a key application of AIoT in healthcare, enabling healthcare providers to monitor patients’ health in real time and intervene when necessary. Rigid-flex PCBs facilitate the development of devices that can transmit data securely and reliably.

Applications:

- Telemedicine Devices: Rigid-flex PCBs enable the integration of communication modules in telemedicine devices, allowing patients to consult with healthcare providers remotely.

- Chronic Disease Management: In devices for managing chronic conditions, such as diabetes and hypertension, rigid-flex PCBs support continuous monitoring and data transmission, enabling timely interventions.

4. Enabling Real-Time Data Processing

Real-time data processing is essential for AIoT medical devices, enabling immediate analysis and response. Rigid-flex PCBs provide the platform for integrating high-performance processors and memory modules that support real-time data processing.

Applications:

- AI-Driven Diagnostics: Rigid-flex PCBs enable the integration of AI algorithms that can analyze medical data in real time, providing accurate and timely diagnostics.

- Surgical Robots: In robotic surgery systems, rigid-flex PCBs support real-time data processing and control, enabling precise and efficient surgical procedures.

5. Enhancing Durability and Reliability

Medical devices often operate in demanding environments, where they may be exposed to moisture, temperature fluctuations, and mechanical stress. Rigid-flex PCBs are designed to withstand these conditions, ensuring reliable operation.

Applications:

- Hospital Equipment: In devices like infusion pumps and ventilators, rigid-flex PCBs provide the durability needed for continuous operation in hospital settings.

- Outdoor Medical Devices: In portable medical devices used in field conditions, rigid-flex PCBs ensure reliable performance despite exposure to harsh environments.

6. Facilitating Miniaturization and Portability

The miniaturization of medical devices is a key trend in healthcare, enabling the development of portable and user-friendly devices. Rigid-flex PCBs enable the integration of multiple functions into compact designs, enhancing portability and usability.

Applications:

- Portable Monitors: Rigid-flex PCBs enable the development of portable monitors for vital signs, such as heart rate and blood oxygen levels, allowing patients to monitor their health on the go.

- Wearable Sensors: In wearable sensors for monitoring physical activity and sleep patterns, rigid-flex PCBs provide the flexibility and durability needed for continuous use.

7. Driving Innovation in Medical AIoT

Rigid-flex PCBs are driving innovation in medical AIoT by enabling the development of new technologies and applications. For example, the integration of AI algorithms and advanced sensors is becoming increasingly feasible with the capabilities of rigid-flex PCBs.

Applications:

- AI-Driven Predictive Analytics: Rigid-flex PCBs enable the integration of AI algorithms that can predict potential health issues based on real-time data, enabling proactive interventions.

- Smart Implants: In smart implants, such as drug delivery systems, rigid-flex PCBs support real-time monitoring and control, improving treatment outcomes.

Conclusion

Rigid-flex PCBs are playing a transformative role in the healthcare industry, enabling the development of advanced AIoT medical devices that improve patient care, enhance diagnostic accuracy, and streamline healthcare operations. By enabling compact and wearable designs, enhancing diagnostic accuracy, supporting remote patient monitoring, enabling real-time data processing, enhancing durability and reliability, facilitating miniaturization and portability, and driving innovation, rigid-flex PCBs are helping to create a smarter and more efficient healthcare system. As the demand for AIoT medical devices continues to grow, rigid-flex PCBs will remain at the forefront of technological innovation, empowering healthcare providers to deliver better care and improve patient outcomes.