Benefits of Using Rigid Flex PCBs in Aerospace and Defense Applications

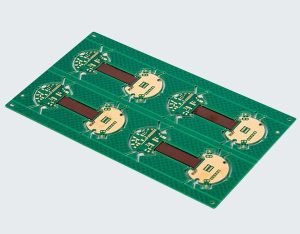

Rigid flex PCBs, or printed circuit boards, have become increasingly popular in aerospace and defense applications due to their unique design and numerous benefits.

These specialized PCBs combine the best of both rigid and flexible circuit boards, offering a high level of reliability and durability in demanding environments. In this article,

we will explore the benefits of using rigid flex PCBs in aerospace and defense applications.

One of the key advantages of rigid flex PCBs is their ability to reduce the overall size and weight of electronic devices.

By combining rigid and flexible materials in a single board, designers can create compact and lightweight solutions that are ideal for space-constrained applications.

This is particularly important in aerospace and defense, where every ounce and inch of space matters.

Additionally, rigid flex PCBs offer improved reliability compared to traditional rigid or flexible boards.

The combination of rigid and flexible materials allows for better distribution of stress and strain, reducing the risk of mechanical failures.

This is crucial in aerospace and defense applications, where electronic systems must operate flawlessly in harsh conditions.

Furthermore, rigid flex PCBs are highly resistant to vibration and shock, making them ideal for use in aerospace and defense applications where equipment may be subjected to extreme conditions.

The flexible portions of the board help absorb and dissipate vibrations, while the rigid portions provide structural support and protection. This results in a more robust and reliable electronic system.

Another benefit of using rigid flex PCBs in aerospace and defense applications is their ability to withstand high temperatures and thermal cycling.

The materials used in these boards are chosen for their thermal stability, allowing them to operate effectively in environments with wide temperature ranges.

This is essential for electronic systems that may be exposed to extreme heat or cold.

In addition to their mechanical and thermal properties, rigid flex PCBs offer excellent signal integrity and electromagnetic interference (EMI) shielding.

The combination of rigid and flexible materials helps minimize signal loss and cross-talk, ensuring reliable communication between components.

This is critical in aerospace and defense applications where data transmission must be fast and accurate.

Moreover, rigid flex PCBs are highly customizable, allowing designers to create complex and intricate layouts that would be difficult or impossible with traditional PCBs.

This flexibility enables the integration of multiple components and functions into a single board, reducing the need for additional interconnects and simplifying the overall design.

This can lead to cost savings and improved performance in aerospace and defense applications.

Overall, the benefits of using rigid flex PCBs in aerospace and defense applications are clear. These specialized boards offer a unique combination of size, weight, reliability, durability,

and performance that make them ideal for demanding environments. As technology continues to advance, rigid flex PCBs will likely play an increasingly important role in the

development of next-generation electronic systems for aerospace and defense.