Benefits of Using Rigid-Flex PCBs in Aerospace and Defense Applications

Rigid-flex PCBs have become increasingly popular in aerospace and defense applications due to their numerous benefits.

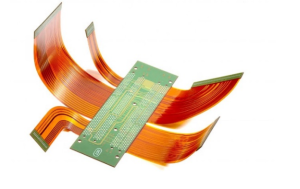

These specialized circuit boards combine the advantages of rigid and flexible PCBs, offering a unique solution for applications that require both durability and flexibility.

In this article, we will explore the benefits of using rigid-flex PCBs in aerospace and defense applications.

One of the key advantages of rigid-flex PCBs is their ability to reduce the overall size and weight of electronic devices.

By combining rigid and flexible sections into a single board, designers can create compact and lightweight solutions that are ideal for space-constrained environments.

This is particularly important in aerospace and defense applications, where every gram of weight saved can have a significant impact on performance and efficiency.

In addition to their compact size and lightweight design, rigid-flex PCBs also offer improved reliability and durability compared to traditional PCBs.

The flexible sections of the board are designed to withstand bending and flexing without compromising the integrity of the circuitry, making them ideal for applications that require frequent movement or vibration.

This level of durability is crucial in aerospace and defense applications, where electronic devices are often subjected to harsh environmental conditions and extreme temperatures.

Another benefit of using rigid-flex PCBs in aerospace and defense applications is their ability to simplify the assembly process.

By integrating multiple PCBs into a single rigid-flex board, designers can reduce the number of interconnects and solder joints, which can help to minimize the risk of signal interference and improve overall reliability.

This streamlined assembly process also helps to reduce the overall cost of production, making rigid-flex PCBs a cost-effective solution for aerospace and defense applications.

Furthermore, rigid-flex PCBs offer enhanced design flexibility, allowing designers to create complex and intricate circuit layouts that would be difficult or impossible to achieve with traditional PCBs.

This level of design flexibility is particularly important in aerospace and defense applications, where electronic devices must meet strict performance requirements and operate in challenging environments.

Rigid-flex PCBs can be customized to meet the specific needs of each application, ensuring optimal performance and reliability.

In conclusion, the benefits of using rigid-flex PCBs in aerospace and defense applications are clear.

These specialized circuit boards offer a unique combination of compact size, lightweight design, durability, reliability, and design flexibility, making them an ideal solution for a wide range of electronic devices.

By incorporating rigid-flex PCBs into their designs, aerospace and defense manufacturers can create innovative and reliable products that meet the demanding requirements of their customers.