Enhancing Wearable Technology with Durable Rigid-Flex PCBs

In the rapidly evolving world of wearable technology, the integration of electronics into fabrics has opened up new possibilities for innovative applications.

One key advancement in this field is the use of durable rigid-flex PCBs in washable smart clothing and e-textiles.

These flexible printed circuit boards offer a robust and reliable solution for embedding electronics seamlessly into textiles, allowing for the creation of more functional and comfortable wearable devices.

The Rise of Wearable Technology

Wearable technology has become increasingly popular in recent years for its ability to enhance our daily lives.

From fitness trackers and smartwatches to medical monitoring devices and smart clothing, wearables have revolutionized how we interact with and benefit from technology.

One of the key challenges in developing wearable devices is ensuring that the electronics are both functional and comfortable to wear.

This is where durable rigid-flex PCBs play a crucial role.

Understanding Rigid-Flex PCBs

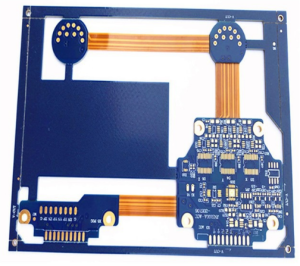

Rigid-flex PCBs are a hybrid type of circuit board that combines the benefits of both rigid and flexible PCBs.

The rigid sections provide structural support and stability for components, while the flexible sections allow for bending and conforming to the shape of the textiles.

This unique design makes rigid-flex PCBs ideal for applications where space is limited, and bending or movement is required.

Advantages of Durable Rigid-Flex PCBs

When it comes to washable smart clothing and e-textiles, durability is a key factor in ensuring the longevity and functionality of the embedded electronics.

Traditional PCBs are often not suitable for textile integration due to their rigid nature, which can lead to damage during bending or washing.

Durable rigid-flex PCBs, on the other hand, are designed to withstand bending, stretching, and washing cycles without compromising the performance of the electronics.

Innovative Applications

The use of durable rigid-flex PCBs opens up a wide range of innovative applications for smart clothing and e-textiles.

From temperature-regulating fabrics to biometric monitoring garments, the possibilities are endless.

For example, a smart shirt embedded with durable rigid-flex PCBs could monitor the wearer’s heart rate, track their activity levels, and even provide feedback on their posture.

This seamless integration of electronics into textiles offers a new level of functionality and comfort for wearable devices.

Challenges and Considerations

While durable rigid-flex PCBs offer many advantages for wearable technology, there are also challenges to consider.

Designing and manufacturing these specialized PCBs require expertise and precision to ensure that they meet the specific requirements of the application.

Additionally, the integration of electronics into textiles poses challenges in terms of waterproofing, washability, and comfort.

Addressing these considerations is crucial to the success of wearable technology products.

Conclusion

In conclusion, the use of durable rigid-flex PCBs in washable smart clothing and e-textiles represents a significant advancement in the field of wearable technology.

By combining the durability of rigid PCBs with the flexibility of flexible PCBs, these specialized circuit boards enable the seamless integration of electronics into textiles, opening up new possibilities for innovative wearable devices. As technology continues to advance, we can expect to see more sophisticated and functional smart clothing and e-textiles powered by durable rigid-flex PCBs.