Rigid-Flex PCBs and the Evolution of Edge Computing in AIoT

Rigid-Flex PCBs and the Evolution of Edge Computing in AIoT

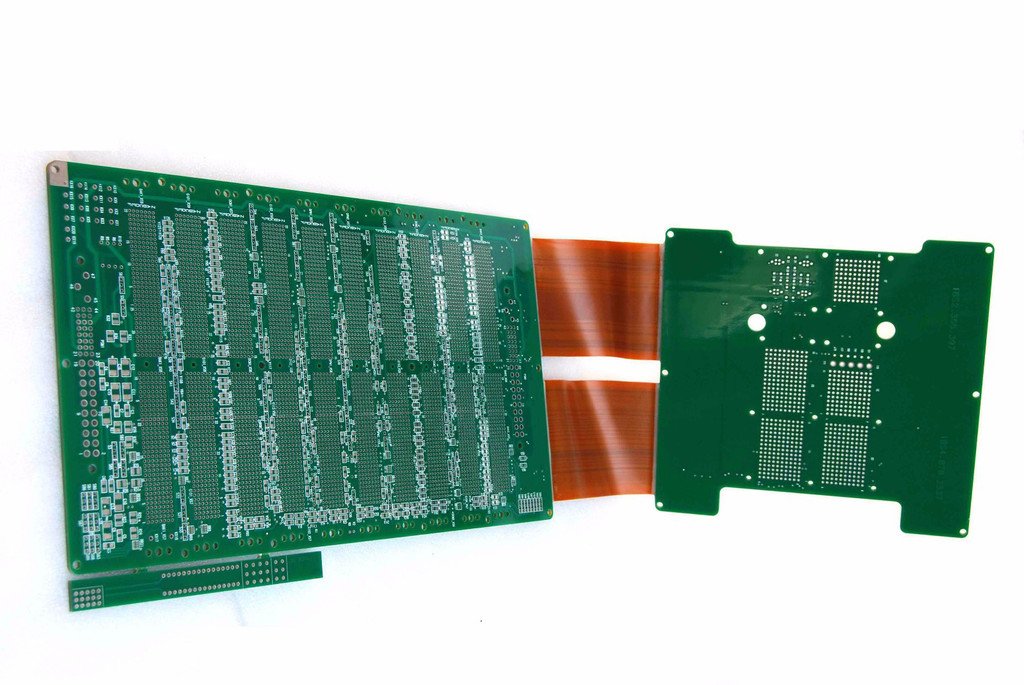

Edge computing is revolutionizing the Artificial Intelligence of Things (AIoT) by enabling real-time data processing and decision-making at the edge of the network, closer to where data is generated. This approach reduces latency, improves efficiency, and enhances the overall performance of AIoT systems. Rigid-flex printed circuit boards (PCBs) are playing a critical role in this evolution, providing the compact, durable, and high-performance platforms needed to support edge computing in AIoT devices.

1. Enabling Compact and Efficient Edge Devices

Edge computing requires devices that can process data locally, often in space-constrained environments. Rigid-flex PCBs are ideal for this purpose, as they combine the structural stability of rigid boards with the flexibility of flexible circuits, allowing for compact and efficient designs.

Applications:

- Smart Cameras: Rigid-flex PCBs enable the integration of high-resolution sensors, processors, and memory modules into compact cameras that can perform real-time image analysis at the edge.

- Wearable Devices: In healthcare and fitness, rigid-flex PCBs support the development of wearable devices that can process biometric data locally, reducing the need for constant cloud connectivity.

2. Supporting High-Performance Computing

Edge computing devices often require high-performance computing capabilities to process large amounts of data in real time. Rigid-flex PCBs provide the necessary platform for integrating advanced processors, memory modules, and communication chips.

Applications:

- Industrial AIoT: In smart factories, rigid-flex PCBs enable the integration of edge computing capabilities into robotic arms and control systems, allowing for real-time decision-making and automation.

- Autonomous Vehicles: Rigid-flex PCBs support the integration of AI processors and sensors in autonomous vehicles, enabling real-time navigation and obstacle detection.

3. Enhancing Durability for Harsh Environments

Edge computing devices are often deployed in harsh environments, such as industrial settings or outdoor locations, where they may be exposed to extreme temperatures, vibrations, and moisture. Rigid-flex PCBs are designed to withstand these conditions, ensuring reliable operation.

Applications:

- Smart Grids: Rigid-flex PCBs used in smart grid sensors and control systems can endure extreme temperatures and mechanical stress, ensuring continuous monitoring and control of energy distribution.

- Outdoor Surveillance: In outdoor surveillance cameras, rigid-flex PCBs provide the durability needed to withstand weather conditions and physical tampering.

4. Facilitating Real-Time Data Processing

One of the key benefits of edge computing is the ability to process data in real time, reducing latency and improving response times. Rigid-flex PCBs enable the integration of high-speed processors and memory modules that support real-time data processing.

Applications:

- Healthcare Monitoring: In medical devices, rigid-flex PCBs enable real-time processing of patient data, allowing for immediate alerts and interventions.

- Traffic Management: In smart traffic systems, rigid-flex PCBs support real-time data processing for adaptive traffic signal control and congestion management.

5. Reducing Latency and Bandwidth Usage

By processing data locally, edge computing reduces the need for constant data transmission to the cloud, thereby reducing latency and bandwidth usage. Rigid-flex PCBs enable the development of devices that can perform complex computations locally, minimizing the reliance on cloud infrastructure.

Applications:

- Smart Homes: In smart home devices, such as security cameras and voice assistants, rigid-flex PCBs enable local data processing, reducing latency and improving user experience.

- Retail Analytics: In retail environments, rigid-flex PCBs support edge devices that analyze customer behavior in real time, enabling personalized marketing and inventory management.

6. Supporting AI-Driven Edge Computing

AI-driven edge computing is becoming increasingly important in AIoT, enabling devices to analyze data and make decisions autonomously. Rigid-flex PCBs provide the platform for integrating AI processors and sensors that support these capabilities.

Applications:

- Predictive Maintenance: In industrial settings, rigid-flex PCBs enable edge devices to analyze equipment data and predict potential failures, reducing downtime and maintenance costs.

- Autonomous Drones: In drones, rigid-flex PCBs support AI-driven navigation and obstacle detection, enabling autonomous operation in complex environments.

7. Driving Innovation in Edge Computing

As edge computing continues to evolve, rigid-flex PCBs are driving innovation by enabling the development of new technologies and applications. For example, the integration of 5G communication modules and advanced AI algorithms is becoming increasingly feasible with the capabilities of rigid-flex PCBs.

Applications:

- 5G-Enabled Edge Devices: Rigid-flex PCBs support the integration of 5G modules, enabling high-speed communication and low-latency data processing at the edge.

- AI-Driven Analytics: By supporting advanced AI processors, rigid-flex PCBs enable edge devices to perform complex data analytics and decision-making autonomously.

Conclusion

Rigid-flex PCBs are playing a transformative role in the evolution of edge computing in AIoT. By enabling compact and efficient designs, supporting high-performance computing, enhancing durability, facilitating real-time data processing, reducing latency, supporting AI-driven capabilities, and driving innovation, rigid-flex PCBs are helping to create smarter, more efficient, and more reliable edge computing devices. As AIoT continues to grow, the demand for advanced edge computing solutions will only increase, ensuring that rigid-flex PCBs remain at the forefront of technological innovation.