Rigid-Flex PCB Prototyping vs. Mass Production: Cost Considerations

Rigid-Flex PCB prototyping brings an exciting blend of flexibility and reliability to the world of electronics.

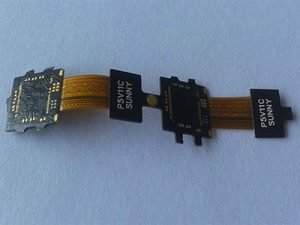

These advanced circuit boards combine the best features of rigid and flexible printed circuit boards (PCBs) into a single solution.

While they are often essential in high-performance applications, understanding the cost considerations associated with prototyping versus mass production is crucial for manufacturers and designers alike.

Understanding Rigid-Flex PCBs

Rigid-Flex PCBs integrate both rigid and flexible substrates, allowing the design to incorporate complex layouts while maintaining durability and functionality.

This makes them popular in industries such as aerospace, medical devices, and consumer electronics, where space-saving designs and lightweight components are essential.

Benefits of Rigid-Flex PCBs

The benefits of Rigid-Flex PCBs extend beyond their structural advantages. They offer improved signal integrity, reduced weight, and enhanced design freedom.

By minimizing the number of interconnections required, they can bolster consistency and reliability while also reducing assembly complexity.

These attributes make Rigid-Flex PCBs particularly appealing in applications where performance and space are critical.

Cost Considerations in Prototyping

When it comes to prototyping Rigid-Flex PCBs, several factors influence costs.

The initial investment tends to be higher compared to standard rigid PCBs due to the complexity of the manufacturing process.

Here are some key considerations:

Design Complexity

The design stage for a Rigid-Flex PCB can be intricate.

Engineers must consider not just the electronic pathways but also mechanical aspects—how the board will flex and where it will be subjected to stress.

This complexity can increase design costs as specialized software and expertise may be required.

Material Selection

The materials used in Rigid-Flex PCBs can significantly impact costs.

High-quality substrates, such as polyimide films, are more expensive but necessary for ensuring durability and flexibility.

During prototyping, making informed material choices is crucial to balance performance needs and cost.

Set-up and Creation Time

Prototyping Rigid-Flex PCBs requires a longer set-up time compared to traditional boards.

The manufacturing process includes multiple steps—such as lamination and etching—that can take longer due to the need for precision.

This extra time translates to higher labor costs, which can become a major factor for smaller projects or companies with tighter budgets.

Mass Production: Cost Efficiency and Challenges

Mass production of Rigid-Flex PCBs presents its own set of cost considerations.

While the per-unit costs generally decrease due to economies of scale, several challenges can arise during the manufacturing process.

Volume Discounts

One of the significant benefits of mass production is the potential for volume discounts on materials and manufacturing processes.

Suppliers often reduce prices based on the quantity ordered, making it more cost-effective as production scales up.

Businesses that can forecast a high volume of sales will find mass production more financially appealing.

Stress on Design and Quality Control

High-volume manufacturing can lead to stress on design specifications. While mass production can lower costs, any design flaws may be exponentially amplified, resulting in increased waste or recalls. Prioritizing robust design reviews and testing during the prototyping phase can mitigate these risks but does add to initial costs.

Tooling and Setup Costs

Despite the potential for savings in mass production, the upfront tooling costs must be considered. Creating molds and machinery specifically for Rigid-Flex PCBs can require significant investment. However, once an initial set-up is completed, the cost per unit reveals notable savings over time.

Balancing Prototyping and Mass Production

When weighing the costs associated with Rigid-Flex PCB prototyping versus mass production, companies must assess their specific needs. Short-run production or limited projects may benefit from prototyping, while stable demand could justify a shift toward mass production.

Strategic Planning

Strategic planning is crucial in determining when to transition from prototyping to mass production. This transition often requires careful cost analysis and market assessment to avoid over-investing in inventory or underestimating demand.

Future Trends

As technology continues to evolve, the costs associated with Rigid-Flex PCBs are expected to reduce over time. Innovations in manufacturing processes and materials could lead to more affordable prototyping options and reduced mass production costs, making these essential components even more accessible for businesses of all sizes.

In summary, Rigid-Flex PCB prototyping versus mass production presents a complex interplay of cost and quality considerations. By understanding the factors that influence expenses in both scenarios, manufacturers can make informed decisions that align with their project goals and budget constraints. Whether advancing in prototyping or transitioning to mass production, understanding the nuances helps ensure long-term success and efficiency in the electronics landscape.