Avoiding Common Mistakes in Rigid-Flex PCB Design: Expert Guidelines

Avoiding common mistakes in rigid-flex PCB design is crucial for ensuring the success and reliability of your electronic products.

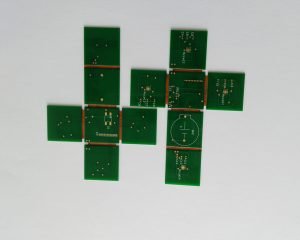

Rigid-flex PCBs combine the best of both rigid and flexible circuit designs, but they come with unique challenges that can lead to costly errors if not addressed properly.

In this article, we will explore the key guidelines that can help you sidestep typical pitfalls associated with rigid-flex PCB design.

Understanding Rigid-Flex PCBs

Rigid-flex PCBs are hybrid circuits that combine rigid and flexible PCBs into a single structure.

This configuration allows for more compact designs, which is particularly beneficial for industries such as aerospace, medical devices, and consumer electronics.

However, this versatility brings complexities in design and manufacturing that can lead to mistakes if not carefully navigated.

Common Design Mistakes to Avoid

1. Inadequate Material Selection

One of the first steps in designing a rigid-flex PCB is selecting the appropriate materials.

This involves not just choosing the right dielectric materials but also understanding their environmental and performance characteristics.

Epoxy, polyimide, and other materials should be considered based on the specific applications and expected thermal and mechanical stress.

2. Neglecting Electrical Design Considerations

Electrical design is fundamental when integrating rigid and flexible sections.

Many engineers mistakenly assume that the electrical performance in the flexible areas will equate to those in rigid regions.

However, variations in impedance, crosstalk, and signal integrity can occur if the flexible parts aren’t designed with the same considerations as the rigid parts.

Ensure you account for trace width, spacing, and layer stacking in your overall design.

3. Ignoring Mechanical Stress

Rigid-flex PCBs have to withstand bending and twisting during their lifecycle, especially in portable devices.

A common mistake is failing to predict how mechanical stress will affect the integrity of the PCB over time.

It’s essential to conduct mechanical analysis and simulations to identify potential failure points.

Make sure that flex regions have appropriate bending radii and reinforcement to handle stress without cracking or delaminating.

4. Overcomplicating the Design

While rigid-flex designs offer great flexibility (pun intended), overcomplicating the layout can lead to manufacturing difficulties and performance issues.

It’s important to keep the design as simple as possible while meeting functional requirements.

Avoid complex routes and several vias in the flexible areas, as these can introduce unwanted capacitance and affect signal integrity.

Best Practices for Rigid-Flex PCB Design

1. Collaborate Early and Often

Involve manufacturers and suppliers early in the design process.

Given the complex nature of rigid-flex PCBs, communication with production partners can help identify potential issues before they arise.

This collaboration can streamline the prototyping phase and reduce the likelihood of costly rework down the line.

2. Conduct Thorough Testing

Testing plays a crucial role in the iteration process of your design.

Utilize both electrical and mechanical testing to assess the durability and performance of your PCB.

Ensure that you employ thermal cycling tests, humidity tests, and mechanical strain tests to gauge how the design will hold up during real-world applications.

3. Leverage Advanced Design Software

Modern design tools offer advanced simulation capabilities that can help identify potential issues before they become actual problems.

Using software that specializes in PCB design can assist in optimizing layout, analyzing signal integrity, and predicting how the board will perform mechanically and electrically.

Final Thoughts

Avoiding common mistakes in rigid-flex PCB design requires a combination of thoughtful planning, proper material selection, and collaboration with relevant stakeholders.

By understanding the unique challenges that come with this type of PCB, and by employing best practices, you can significantly improve the reliability and performance of your designs.

Ultimately, meticulous attention to detail and proactive testing will pave the way for successful products that meet and exceed market demands.

By adhering to these expert guidelines, designers can transform the rigid-flex PCB domain from a minefield of errors into a landscape of innovation and efficiency.